- Home

- >

- Products

- >

- S7 Tool Steel

- >

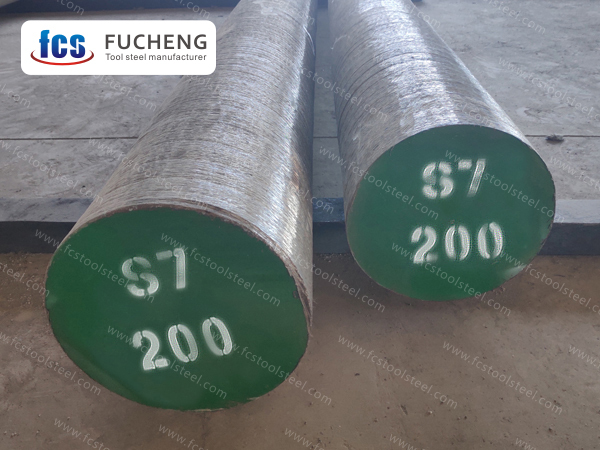

S7 Tool Steel

S7 steel is a kind of air or Oil hardened tool steel with high impact toughness. The combination of strength and high toughness makes it a candidate for various tool applications.

S7 tool steel is often used for cold working tools that need to resist high impact and impact loads, such as shear blades, forging dies, clamping dies, chisels and punches.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

S7 STEEL

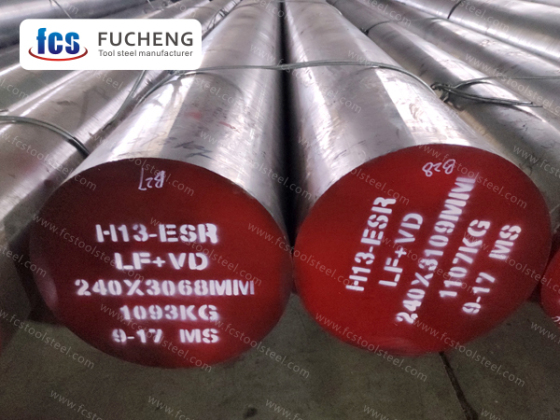

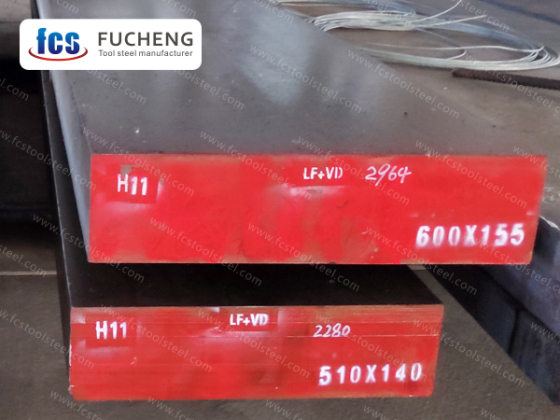

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤229 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

S7 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ASTM | S7 | 0.45~0.55 | 0.20~1.00 | 0.20~0.90 | 3.00~3.50 | 1.30~1.80 | ≤0.35 |

| GB | 5Cr3Mn1SiMo1V | 0.45~0.55 | 0.20~1.00 | 0.20~0.90 | 3.00~3.50 | 1.30~1.80 | ≤0.35 |

APPLICATION

S7 is impact resistant tool steel, which can be used as punching or punching tools, shear dies, hot forging dies, die casting dies of fusible alloys, and blades for hot and cold metal shearing.

S7 STEEL CHARACTERISTICS

S7 steel is a high-quality chromium molybdenum alloy tool steel with many excellent characteristics. As a type of steel with high hardness and wear resistance, S7 steel has been widely used in many fields.

Firstly, S7 steel has excellent hardenability. This enables it to quickly achieve the required hardness and strength during the heat treatment process, and has high toughness. This hardenability makes S7 steel an ideal choice for manufacturing various cutting tools, punches, and molds. Whether used for cutting, stamping, or forming, S7 steel can provide excellent performance and durability.

Secondly, S7 steel has high strength and tempering stability. It has high tensile strength and yield strength, and can maintain its strength and hardness even in high temperature environments. This makes S7 steel very useful in manufacturing tools that need to withstand high loads and impacts. Whether used as cutting tools for heavy-duty machinery or high-strength parts in automotive manufacturing, S7 steel can provide excellent performance.

In addition, S7 steel also has high impact toughness and wear resistance. Its toughness makes it less prone to fracture or deformation when subjected to impact, thereby extending its service life. Meanwhile, the surface of S7 steel has good wear resistance, enabling it to maintain good performance in high-speed cutting and wear environments. This makes S7 steel an ideal choice for manufacturing cutting tools, punches, and molds.

In addition, S7 steel also exhibits high hardening and softening resistance. Its hardness can be precisely controlled during the heat treatment process to meet different application requirements. This makes S7 steel very suitable for manufacturing tools that require specific hardness and strength. At the same time, S7 steel also has excellent softening resistance, which can maintain its hardness and strength even at high temperatures, thereby extending its service life.

In addition, S7 steel also exhibits excellent mechanical fatigue resistance. It can maintain stable performance under repeated loads and is less prone to fatigue fracture. This gives S7 steel a great advantage in manufacturing tools and parts that require long-term use. Whether used as cutting tools for mechanical equipment or key components of automotive engines, S7 steel can provide reliable performance.

Finally, S7 steel also possesses high toughness and medium temperature oxidation resistance. Its toughness makes it less prone to fracture or deformation under impact, providing a longer service life. At the same time, S7 steel has good oxidation resistance in the medium temperature range and can resist the influence of oxidation corrosion. This makes S7 steel not only suitable for manufacturing tools and dies that work at higher temperatures, but also for manufacturing parts that are used at moderate temperatures.