- Home

- >

- Products

- >

- H11 Tool Steel

- >

H11 Tool Steel

H11 steel is often used to manufacture die-casting die, hot extrusion die, punching tool and mandrel of aluminum castings, as well as hammer forging die with complex cavity and large impact load, integral die or insert of forging press, high wear-resistant plastic die, etc.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

H11 TOOL STEEL

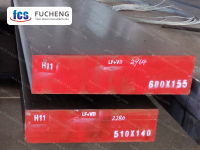

| Smelting and Manufacture Method: | LF+VD+ESR+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤229 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

H11 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ASTM | H11 | 0.33~0.43 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.60 | 0.30~0.60 |

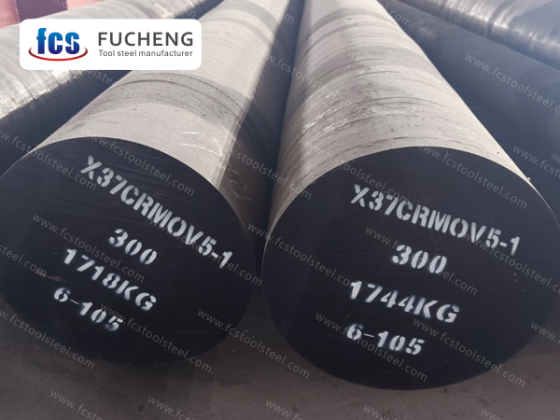

| DIN/W-Nr. | X38CrMoV5-1/1.2343 | 0.36~0.42 | 0.90~1.20 | 0.30~0.50 | 4.80~5.80 | 1.10~1.40 | 0.25~0.50 |

| JIS | SKD6 | 0.32~0.42 | 0.80~1.20 | ≤0.50 | 4.50~5.50 | 1.00~1.50 | 0.30~0.50 |

APPLICATION

As a typical representative of hot work die steel, H11 steel has demonstrated wide applicability under high temperature and high pressure conditions due to its excellent thermal strength and thermal fatigue resistance. H11 steel has outstanding performance in the field of aluminum/magnesium alloy die-casting, and can withstand repeated impacts of molten metal at 600-700 ℃, making it particularly suitable for manufacturing key components such as sprue sleeves and cores;

The alloy design of H11 steel with 5.5% chromium and 1.5% molybdenum ensures that the hot extrusion die maintains a hardness of 52-54HRC at 400-550 ℃, and is commonly used for continuous extrusion production of copper pipes and aluminum profiles. After improving the transverse toughness of H11 steel through isotropic forging process, precision forging dies for complex forgings such as automobile crankshafts and connecting rods can be made, which can withstand impact loads of over 2000 tons without cracking. The surface hardness of H11 steel treated with nitriding can reach 1100HV, and its lifespan for injection molding of glass fiber reinforced plastics can be 5-8 times that of ordinary P20 steel. It has significant advantages in precision plastic parts such as automotive lampshades and electronic connectors. H11 steel is also suitable for special scenarios such as copper alloy gravity casting molds and titanium alloy isothermal forging dies.

H11 STEEL CHARACTERISTICS

H11 steel is an air cooled and hardened hot work mold steel widely used in the manufacturing of various types of molds and tools. This type of steel has fine and uniformly distributed carbides, thus possessing excellent cold and hot fatigue resistance and corrosion resistance. In addition, it also has good cold and hot workability and hardenability. At moderate temperatures, H11 steel exhibits high thermal strength, oxidation resistance, as well as excellent toughness and wear resistance.

H11 steel has excellent cold and hot fatigue resistance. During the working process, molds often undergo cyclic changes of high and low temperatures, which can lead to fatigue cracks on the surface of the mold. However, due to the small and uniform distribution of carbides in H11 steel, it can effectively resist the formation and propagation of fatigue cracks, thereby extending the service life of the mold. This makes H11 steel particularly suitable for manufacturing molds that require working in high-temperature environments, such as injection molds, die-casting molds, etc.

H11 steel has good corrosion resistance. When working at high temperatures, the mold may come into contact with corrosive chemicals, which can cause corrosion and damage to the surface of the mold. However, due to the small and uniform distribution of carbides in H11 steel, it can effectively resist the erosion of corrosive substances, thereby protecting the surface quality of the mold. This makes H11 steel particularly suitable for manufacturing molds that require working in high-temperature and humid environments, such as food molds, cosmetics molds, etc.

H11 steel has good cold and hot workability. During the machining process, H11 steel can be easily cut, ground, and drilled, resulting in high machining efficiency. This makes H11 steel particularly suitable for manufacturing molds that require high-precision processing, such as electronic molds, optical molds, etc. In addition, H11 steel also has good hardenability. Through appropriate heat treatment processes, the hardness, strength, and toughness of H11 steel can be adjusted to meet the needs of different working conditions. This gives H11 steel high flexibility and adaptability, which can meet various application needs.

H11 steel has high toughness and wear resistance. During use, H11 steel can absorb significant impact energy and is less prone to fracture and cracking. This makes H11 steel particularly suitable for manufacturing molds that need to withstand significant impact forces, such as stamping molds, extrusion molds, etc. At the same time, H11 steel also has good wear resistance and can withstand significant wear. This makes H11 steel particularly suitable for manufacturing molds that need to withstand significant wear, such as cold drawing molds, cold heading molds, etc.

H11 steel also has good polishing performance. During the polishing process, H11 steel can easily remove surface oxide scale and impurities, achieving a smooth surface quality. This makes H11 steel particularly suitable for manufacturing molds that require high smoothness, such as plastic molds, optical molds, etc.