History

Hubei Fucheng(FCS TOOL STEEL ) started with the brand of Furong Iron and Steel which was established in August 2007 . It is located adjacent to the Xisaishan Industrial Park, Huangshi City, Hubei Province, China,which has the reputation of "the cradle of steel". The company covers an area of 65 acres and has a workshop area of 40,000 square meters , Tool steel output 2000 tons / month, 25000 tons / year, production of cold work tool steel, hot work tool steel, plastic tool steel, alloy tool steel, high speed steel, can be customized ASTM/EN/DIN/JIS/SS standard tool steel ,

FCS tool steel Factory Main Product:

ASTM: A2/D2/D3/D6/O1/H11/H13/H21/L6/S7/420SS/420H/440C

DIN:1.2080/1.2436/1.2601/1.2379/1.2550/1.2510/1.2343/1.2344/1.2714/1.2367/1.2767/1.2083/1.2316

JIS:SKD1/SKD2/SKD11/SKS3/DC53/SKT3/SKT4/SKD5/SKD6/SKD61/SUS420J2

Fucheng Steel(FCS) sincerely invites global tool steel wholesalers, stockists, traders, and terminal tool steel users to come to our factory in China for on-site inspections and establish long-term friendly cooperative relationships!

Our Mission

Since its establishment in 2007, FCS TOOL STEEL has been committed to becoming one of the world's leading special steel suppliers. We insist on providing reliable and high quality cold work tool steel, hot work tool steel, plastic mold steel, high speed tool steel and alloy steel for industrial, military and other applications.

Philosophy & Vision

· Quality is FCS TOOL Steel’s life.

· Reliability is FCS TOOL STEEL ’s code.

· Customer Satisfaction is FCS TOOL STEEL ’s final goal.

· FCS TOOL STEEL is aimed at building wide and firm strategic relationship with customer all over the world on long term and mutually benefit basis.

Our Advantage

-

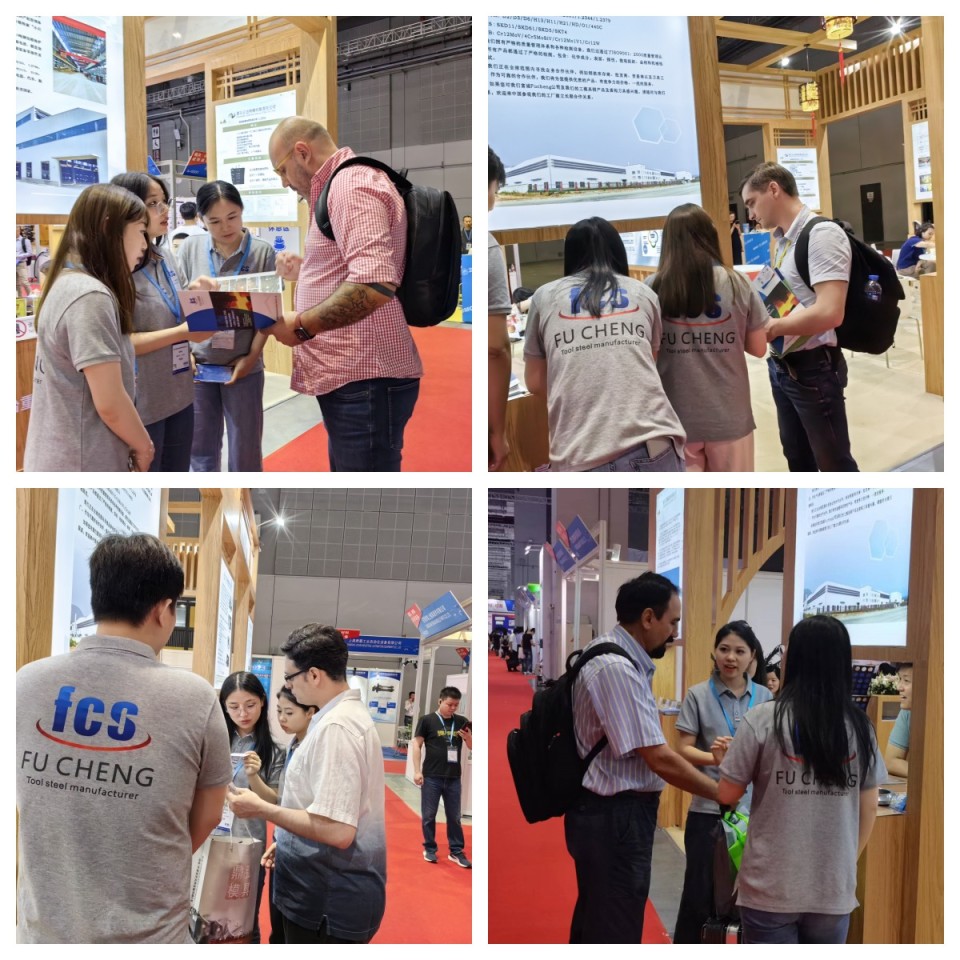

![Die&Mould Exhibition 2023 In Shanghai]() Die&Mould Exhibition 2023 started from the 11th to 14th June in Shanghai.

Die&Mould Exhibition 2023 started from the 11th to 14th June in Shanghai.

At the exhibition, we received many new and old customers, and had wonderful and effective conversations with them.

We are very grateful to them for coming, which made our exhibition a great success.

See you next year!