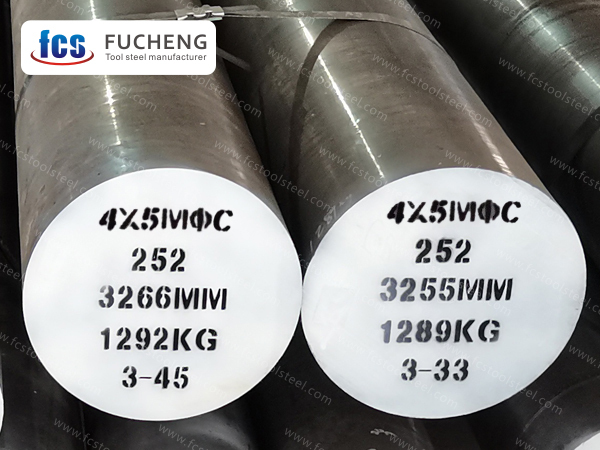

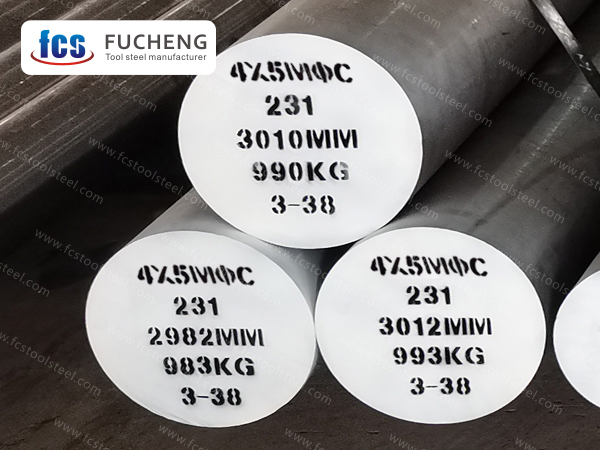

4X5MΦC Hot Work Tool Steel

Сталь 4X5MΦC обладает высокой твердостью и ударной вязкостью и подходит для литья под давлением, экструзии, горячего прессования алюминия, меди, магния.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

4X5MΦC STEEL

| Smelting and Manufacture Method: | LF+VD+ESR+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤229 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

4X5MΦC STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ГOСТ | 4X5MΦC | 0.33~0.42 | 0.80~1.20 | ≤0.50 | 4.60~5.70 | 1.10~1.50 | 0.25~0.55 |

| DIN/W-Nr. | X38CrMoV5-1/1.2343 | 0.36~0.42 | 0.90~1.20 | 0.30~0.50 | 4.80~5.80 | 1.10~1.40 | 0.25~0.50 |

| ASTM | H11 | 0.33~0.43 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.60 | 0.30~0.60 |

APPLICATION

4X5MΦC steel has high hardness and toughness, and is suitable for die casting die, extrusion die, hot pressing die of aluminum, copper, magnesium.

4X5MΦC STEEL CHARACTERISTICS

4X5MΦC steel is a type of hot work mold steel, commonly used for manufacturing various plastic molds, die-casting molds, etc. Due to its carbon content, it has good hardness and strength, as well as good wear and corrosion resistance. In practical applications, In practical applications, the performance of X5MΦC steel may vary due to different heat treatment processes and processing methods.

In terms of physical properties, X5MΦC steel exhibits good thermal strength, oxidation resistance, as well as high toughness and wear resistance at medium temperature. These features make the 4X5MΦC steel can maintain stable performance in various harsh environments. In addition, 4X5MΦC tool steel also has good high-temperature strength, excellent toughness and ductility in all directions, excellent hardenability, and high-level resistance to thermal shock and thermal fatigue. This makes it highly durable and stable for high-speed cutting and drilling. At the same time, its strength is also very high, it can withstand large pressures and loads, and is not easy to deform or fracture. These features make the 4X5MΦC steel has become an ideal choice for manufacturing high-quality molds.

In addition to hardness and strength, 4X5MΦC steel also has good wear resistance and corrosion resistance. During long-term use, it can maintain surface smoothness and accuracy, and is not easily affected by wear and corrosion. This makes it suitable for manufacturing molds that require long-term use, such as injection molds, die-casting molds, etc. Due to its excellent wear resistance and heat resistance, it is also commonly used in extrusion molds, die cores, die pads, liners, and other applications. In addition, it is also applied in hot pressing molds, plastic molds, cold stamping, trimming, hot shearing, compression rings, and wear-resistant parts of aluminum, copper, and magnesium. 4X5MΦC steel also has a certain degree of toughness and ductility, which can maintain a stable shape and size when subjected to impact or vibration.

During the manufacturing process, 4X5MΦC steel can change its physical and mechanical properties through different heat treatment processes. For example, quenching and tempering can improve its hardness and strength; Carburization treatment can improve its surface hardness and wear resistance; Nitriding treatment can improve its corrosion resistance and fatigue strength. These heat treatment processes can be adjusted and applied according to specific needs to meet the requirements of different molds.