AISI H11 Tool Steel | 1.2343 | X37CrMoV5-1 | SKD6 | BH11

H11 air cooling hardening hot working die steel. H11 steel is one of the three most commonly used hot working die steels in the European die casting industry. The carbides in the steel are fine, evenly distributed, good cold and hot fatigue resistance and corrosion resistance, good cold and hot working performance, good hardenability, thick thermal strength, oxidation resistance, high toughness and wear resistance at medium temperature.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

H11 STEEL

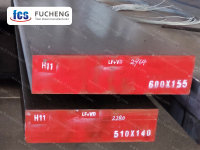

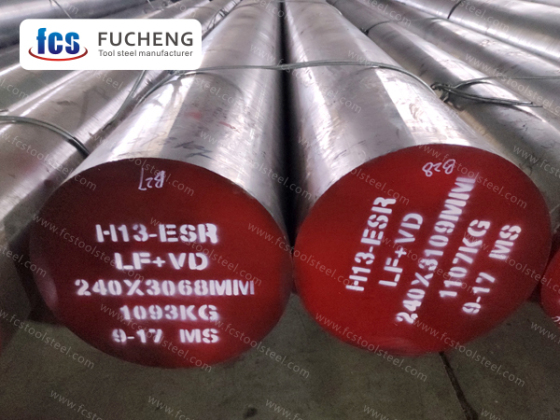

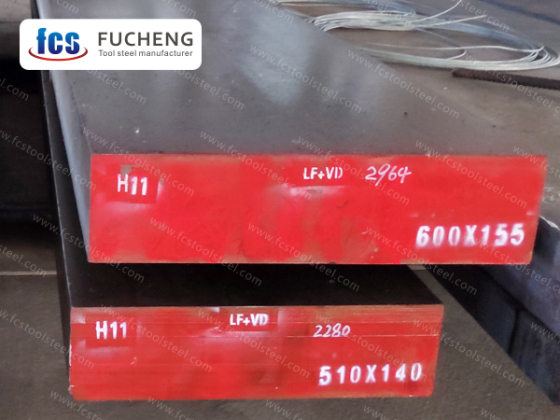

| Smelting and Manufacture Method: | LF+VD+(ESR)+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤229 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

H11 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ASTM | H11 | 0.33~0.43 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.60 | 0.30~0.60 |

| DIN/W-Nr. | X38CrMoV5-1/1.2343 | 0.36~0.42 | 0.90~1.20 | 0.30~0.50 | 4.80~5.80 | 1.10~1.40 | 0.25~0.50 |

| JIS | SKD6 | 0.32~0.42 | 0.80~1.20 | ≤0.50 | 4.50~5.50 | 1.00~1.50 | 0.30~0.50 |

APPLICATION

H11 tool steel is suitable for high-speed hammer forging dies, Aluminum and magnesium alloy hot forging dies

H11 STEEL CHARACTERISTICS

H11 steel, also known as the American air cooled hardened hot work mold steel, is one of the three most commonly used hot work mold steels in the European die casting industry. It has good comprehensive mechanical properties and can maintain high strength and toughness from room temperature to 600 ℃. The carbides in this steel are small and evenly distributed, with good resistance to cold and hot fatigue and corrosion, good cold and hot processing performance, good hardenability, and good thermal strength, oxidation resistance, high toughness, and wear resistance at medium temperatures. It is widely used due to its excellent comprehensive mechanical properties and thermal fatigue resistance.

In terms of chemical composition, the carbides in H11 steel are very small and evenly distributed. This characteristic endows H11 steel with excellent cold and hot fatigue resistance and corrosion resistance. At the same time, it also has good cold and hot processing performance and hardenability.

In terms of physical properties, H11 steel exhibits good thermal strength, oxidation resistance, as well as high toughness and wear resistance at medium temperature. These characteristics enable H11 steel to maintain stable performance in various harsh environments. In addition, H11 tool steel also has good high-temperature strength, excellent toughness and ductility in all directions, excellent hardenability, and a high level of thermal shock resistance and thermal fatigue.

In summary, H11 steel is a hot work mold steel with excellent comprehensive performance, widely used in industries such as automobiles, aviation, and electronics. Its chemical composition and production process have a significant impact on its performance. H11 steel with good comprehensive properties can be obtained through a reasonable heat treatment process. Attention should be paid to preventing corrosion, oxidation, decarburization, wear, and fatigue during use.