HD Hot Work Tool Steel

HD steel is a kind of high toughness, air cooling hardening hot working die steel. HD steel has good high temperature strength and toughness, high temperature hardness, thermal stability and thermal fatigue resistance.

HD steel is often used for hot extrusion punch of steel medicine pipe, extrusion bottom die and perforation needle of copper alloy pipe, hot extrusion bearing punch and concave die, valve extrusion low die and so on. The service life is longer than that of H21 steel.

- Fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

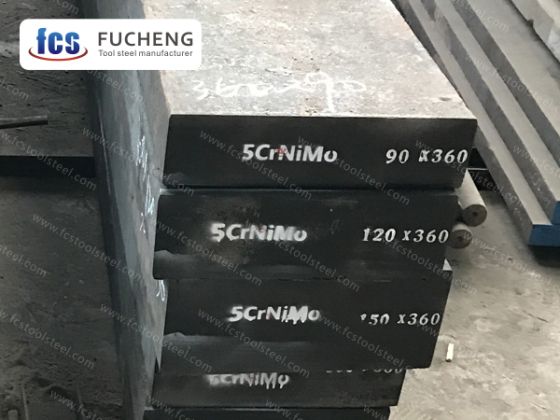

HD HOT WORK TOOL STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤220 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

HD STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||||

| C | Si | Mn | Cr | Mo | V | Ni | Nb | ||

| GB | HD/4Cr3Mo2NiVNb | 0.35~0.45 | ≤0.35 | ≤0.40 | 2.50~3.00 | 1.80~2.20 | 1.00~1.40 | 0.80~1.20 | 0.10~0.25 |

APPLICATION

HD steel is often used for hot extrusion punch of steel medicine pipe, extrusion bottom die and perforation needle of copper alloy pipe, hot extrusion bearing punch and concave die, valve extrusion low die and so on.

HD steel characteristics

HD steel, also known as 4Cr3Mo2VNiNb, is a high toughness hot work mold steel, also known as air cooled hardened steel. This is a steel grade developed by China on the basis of UHBQR080 steel. Unlike many traditional hot work mold steels, HD mold steel does not contain cobalt elements, but adds 1% nickel and trace amounts of niobium, boron and other elements, making it excellent in terms of strength, toughness, hardness, thermal stability, and thermal fatigue resistance at high temperatures.

HD mold steel can maintain good stability and strength at high temperatures, and is not easily softened or deformed. This enables it to maintain excellent mold performance for a long time during high-temperature hot working processes such as forging, die casting, hot extrusion, etc. HD mold steel has excellent wear resistance and can maintain a low wear rate for a long time in high temperature, high pressure, and high friction environments, which helps to improve the service life of molds and reduce production costs. HD mold steel exhibits good toughness and impact resistance when subjected to impact loads, effectively preventing cracking or fracture of the mold during use. HD mold steel has good cutting performance, heat treatment performance, and welding performance, making it easy to process, adjust, and repair during the manufacturing process.

HD steel has a wide range of applications. In terms of cold work molds, they can be used for stamping molds, manufacturing stamping molds for automotive coverings, etc; Suitable for cold heading molds, making fastener cold heading molds; It can also be used for cold extrusion molds, manufacturing pipe fittings, gears, etc. In the field of hot work molds, it can be used as the cavity and core material for die-casting molds, and is used for die-casting of aluminum alloys and other materials; It can also be used for hot forging molds. In plastic molds, it can be used for injection molds with high requirements such as engineering plastics, precision injection molds, as well as extrusion molds, to manufacture plastic pipes, etc. Its excellent performance can ensure the accuracy, quality, and service life of the mold.