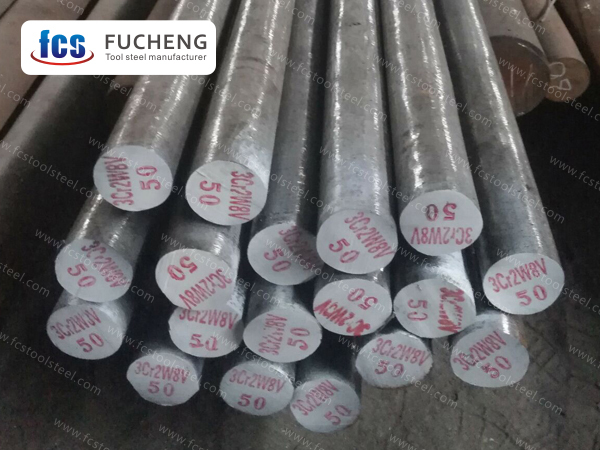

3Cr2W8V Hot Work Tool Steel

3Cr2W8V steel is a tungsten based hot work die steel, with its core highlights being high heat resistance (hardness still reaches HB300 at 600-650 ℃), excellent wear resistance (tungsten content of 7.5-9% forms high hardness carbides), and good fatigue resistance (outstanding resistance to cold and hot alternating performance). 3Cr2W8V steel is particularly suitable for high-temperature, high stress, and impact free working conditions such as die-casting molds and hot extrusion molds.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

3CR2W8V HOT WORK TOOL STEEL

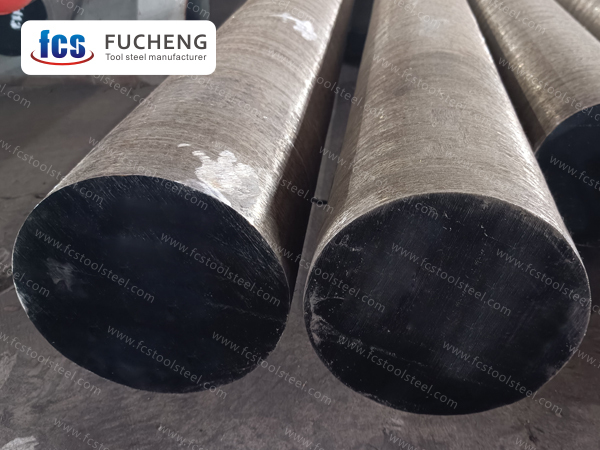

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

3Cr2W8V STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | V | W | ||

| GB | 3Cr2W8V | 0.30~0.40 | ≤0.40 | ≤0.40 | 2.20~2.70 | 0.20~0.50 | 7.50~9.00 |

| DIN/W-Nr. | X30WCrV9-3/1.2581 | 0.25~0.35 | 0.15~0.30 | 0.20~0.40 | 2.50~2.80 | 0.30~0.40 | 8.00~9.00 |

| ASTM | H21 | 0.26~0.36 | 0.15~0.50 | 0.15~0.40 | 3.00~3.75 | 0.30~0.60 | 8.50~10.0 |

APPLICATION

3Cr2W8V steel is widely used in press forging die, hot extrusion die, upsetting die, shear knife, die casting die, precision forging die and non-ferrous metal forming die.

3CR2W8V STEEL CHARACTERISTICS

3Cr2W8V steel is a medium carbon high alloy steel with characteristics including high toughness and good thermal conductivity. The high tungsten content in steel improves the tempering stability of the steel and precipitates carbides during the tempering process, which makes the steel have good red hardness. In addition, the chromium and vanadium elements in the steel further improve the wear and corrosion resistance of the steel.

3Cr2W8V steel is a typical die-casting die steel and is also widely used in other hot work molds. It has high hardness and strength at high temperatures, and its hardness can reach HB300 at 650 ℃. However, due to its high hardness and strength, it is often used as a hot extrusion and die-casting mold due to its poor toughness.

Firstly, for applications that require molds with high hardness and strength, 3Cr2W8V steel is an ideal choice. For example, when manufacturing die-casting molds, it is necessary for the molds to have high hardness and strength to withstand the impact of high-temperature and high-pressure metal liquids. Meanwhile, as the mold needs to work at high temperatures, it needs to have good wear resistance. The high hardness and wear resistance of 3Cr2W8V steel can meet these requirements.

Secondly, for application scenarios that require molds to have good thermal conductivity, 3Cr2W8V steel is also a good choice. Due to the need for the mold to work at high temperatures, it is necessary to have good thermal conductivity to maintain a uniform temperature of the mold. The good thermal conductivity of 3Cr2W8V steel can effectively transmit heat and avoid mold damage due to overheating.

However, it should be noted that due to the poor toughness of 3Cr2W8V steel, it may not be suitable for some application scenarios under impact loads. For example, when manufacturing stamping molds that are subjected to high impact loads, it is necessary for the molds to have a certain degree of toughness to withstand the impact force. In this case, other materials with better toughness can be chosen to manufacture the mold.