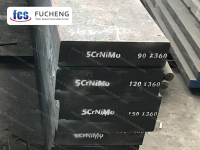

5CrNiMo Hot Work Tool Steel

5CrNiMo tool steel is suitable for manufacturing large and medium-sized hammer forging dies and trimming dies with complex shapes, large impact load and low working temperature.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

5CrNiMo STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤212 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

5CrNiMo STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | |||||||

| C | Si | Mn | Cr | Mo | V | Ni | ||

| GB | 5CrNiMo | 0.50~0.60 | ≤0.40 | 0.50~0.80 | 0.50~0.80 | 0.15~0.30 | - | 1.40~1.80 |

| ASTM | L6 | 0.65~0.75 | 0.10~0.50 | 0.25~0.80 | 0.60~1.20 | ≤0.50 | - | 1.25~2.00 |

| DIN/W-Nr. | 55NiCrMoV6/1.2713 | 0.50~0.60 | 0.10~0.40 | 0.65~0.95 | 0.60~0.80 | 0.25~0.35 | 0.07~0.12 | 1.50~1.80 |

| JIS | SKT4 | 0.50~0.60 | 0.10~0.40 | 0.60~0.90 | 0.80~1.20 | - | 0.05~0.15 | 0.35~0.55 |

APPLICATION

5CrNiMo tool steel is suitable for manufacturing large and medium-sized hammer forging dies and trimming dies with complex shapes, large impact load and low working temperature.

5CRNIMO STEEL CHARACTERISTICS

5CrNiMo steel is a type of hot work mold steel with good toughness, strength, and high wear resistance as its main characteristics. At room temperature and 500-600 ℃, its mechanical properties are almost the same, and when heated to 500 ℃, it can still maintain a hardness of around HB300. Due to the presence of molybdenum element in this steel, it is not sensitive to temper brittleness. After slowly cooling from 600 ℃, its impact toughness only slightly decreases. Furthermore, it is worth emphasizing that 5CrNiMo steel has excellent hardenability, to the point where it resembles 300 × three hundred × Workpieces as large as 400mm can be completely quenched. In addition, although the heat fatigue resistance of 5CrNiMo steel is slightly poor, it has similar properties to H13 steel and slightly inferior hardenability. Therefore, 5CrNiMo steel is widely used in the production of various types of forging dies that require high strength and wear resistance, especially large and medium-sized hammer forging dies.

The chemical composition of 5CrNiMo steel, carbon, is the main element that improves the hardness and strength of the steel, while also having a certain impact on toughness and plasticity. Chromium can improve the oxidation and corrosion resistance of steel, as well as increase its hardness and strength. Nickel can improve the toughness and corrosion resistance of steel, while also improving its processing performance. Molybdenum can improve the hardenability and wear resistance of steel, while also enhancing its oxidation resistance and corrosion resistance.

The heat treatment process of 5CrNiMo steel is as follows: quenching temperature 820-860 ℃, oil cooling or air cooling; Tempering temperature 580-640 ℃, air cooled. This heat treatment process can achieve good hardness and strength of steel, while maintaining high toughness and wear resistance.

The mechanical properties of 5CrNiMo steel are: hardness HRC42-48, tensile strength σ B ≥ 1080MPa, yield strength σ S ≥ 980MPa, elongation δ 5 ≥ 9%, reduction of area ψ≥ 45%. These performance indicators indicate that 5CrNiMo steel has high strength and toughness, and can withstand large impact loads.

5CrNiMo steel is widely used in hammer forging die manufacturing. Due to its excellent performance, it is widely used to manufacture large hammer forging dies with complex shapes and heavy impact loads. For example, it can be used to manufacture forging molds for important components such as automobiles, airplanes, and ships. In addition, it can also be used to manufacture molds for special purposes, such as high-temperature molds, corrosion-resistant molds, etc.

However, there are also some issues with 5CrNiMo steel. Its heat treatment process is relatively complex, requiring strict control of quenching and tempering temperatures, otherwise it will affect the performance of the mold. In addition, when it operates at high temperatures, it may experience softening phenomenon, which affects the service life of the mold.

To address these issues, researchers are researching new steel and heat treatment processes. For example, they are researching the addition of new alloy elements to improve the wear resistance and oxidation resistance of steel; They are also researching new heat treatment processes to simplify the process and reduce production costs.