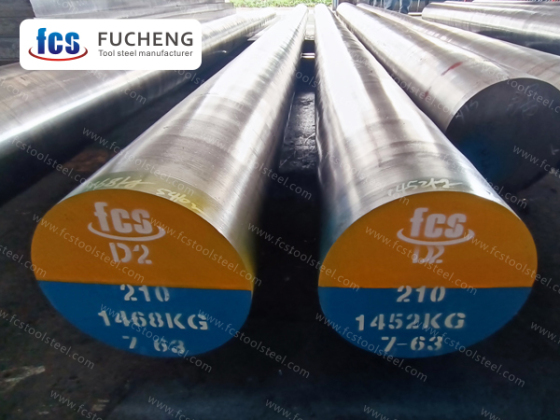

D2 Tool Steel | 1.2379 | X155CrVMo12-1 | SKD11

D2 tool steel is suitable for tool steel with complex deformation, all kinds of cold stamping dies with high wear resistance and long life, cold shear blades, and thread rolling plates; Cold extrusion forming, stretching film, beer stainless steel sheet and balance cutting die of high hardness materials, etc

- Fucheng steel

- China

- 1 month

- 2,000 Tons/ Month

- Information

- Video

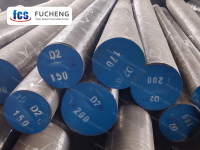

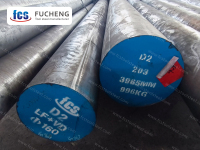

D2 TOOL STEEL

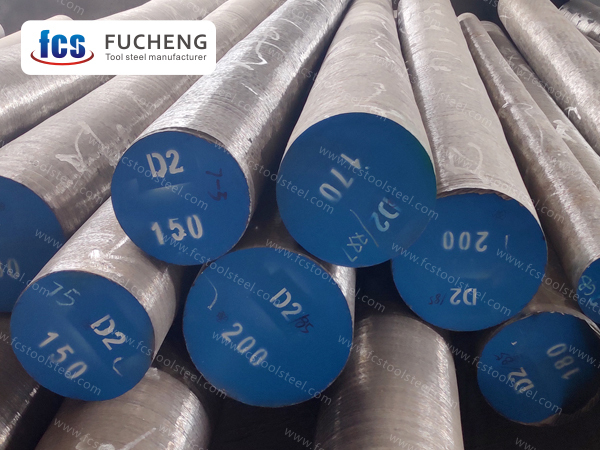

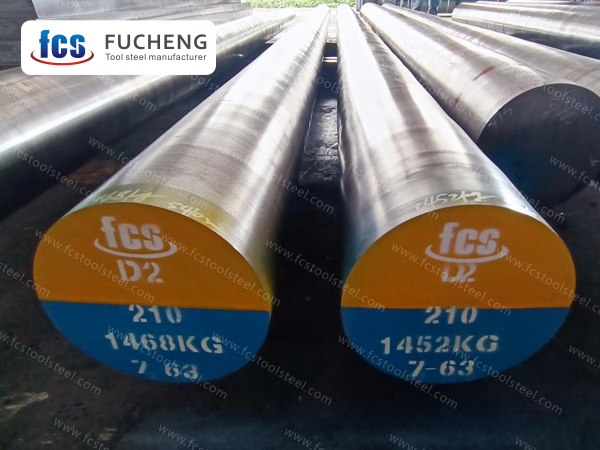

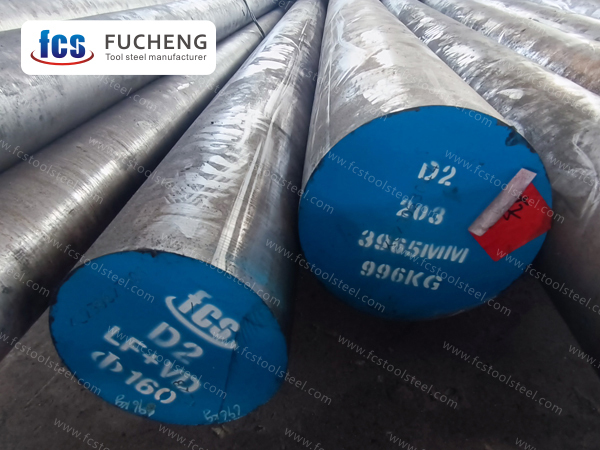

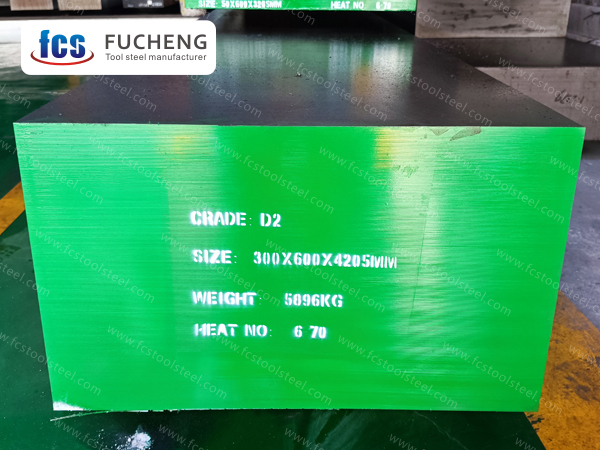

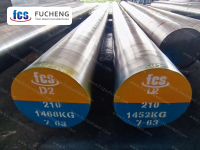

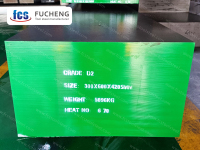

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

D2 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ASTM | D2 | 1.40~1.60 | ≤0.60 | 0.10~0.60 | 11.00~13.00 | 0.70~1.20 | 0.50~1.10 |

| DIN/W-Nr. | X155CrVMo12-1/1.2379 | 1.45~1.60 | ≤0.60 | 0.20~0.60 | 11.00~13.00 | 0.70~1.00 | 0.70~1.00 |

| JIS | SKD11 | 1.40~1.60 | ≤0.40 | ≤0.60 | 11.00~13.00 | 0.80~1.20 | 0.20~0.50 |

APPLICATION

D2 tool steel is suitable for tool steel with complex deformation, all kinds of cold stamping dies with high wear resistance and long life, cold shear blades, and thread rolling plates; Cold extrusion forming, stretching film, beer stainless steel sheet and balance cutting die of high hardness materials, etc

D2 STEEL CHARACTERISTICS

D2 steel is a cold working die steel with high wear resistance and slight deformation, with a carbon mass fraction of up to 1.5% and a chromium mass fraction of up to 11.5%. The characteristic of this type of steel is that its hardness can reach 60HRC through heat treatment. Therefore, D2 steel is very suitable for manufacturing cold working molds with large cross-sections, complex shapes, high impact resistance, and high wear resistance requirements, such as silicon steel sheet punching molds, cold cutting scissors, edge cutting molds, etc.

Due to its high carbon content and the presence of chromium, D2 steel has excellent wear resistance and wear resistance. In high-speed, high-temperature, and high-pressure working environments, it can maintain a stable working state for a long time and is not prone to fatigue and damage. This makes D2 steel exhibit excellent durability and reliability under heavy load and continuous working conditions.

D2 steel also has good strength and hardness, which is determined by its high carbon content. This characteristic enables D2 steel to maintain a stable shape and size under high impact and pressure, and is less prone to deformation or damage. Meanwhile, this also enables D2 steel to ensure the accuracy and repeatability of the mold when producing high-precision molds.

However, although D2 steel has excellent wear resistance and hardness, its ductility, toughness, and rust resistance are relatively weak. This to some extent limits its application in some special environments. Especially in environments with high humidity or corrosive gases, D2 steel may be more prone to rusting or corrosion. Therefore, when using D2 steel under these conditions, special protective measures need to be taken.

In addition, due to its high carbon content, it is best not to heat treat D2 steel if not required. Because the heat treatment process may cause changes in its internal structure, thereby affecting its hardness and wear resistance. If heat treatment is carried out unnecessarily, it may lead to a decrease in the performance of D2 steel, which cannot meet the requirements for use.

In the future development, with the advancement of technology and the improvement of processes, we hope that D2 steel can be applied in more fields, bringing more convenience and benefits to our lives and work. At the same time, we also look forward to developing more new materials to meet the needs of different fields and promote social progress and development.