- Home

- >

- Products

- >

- D2 Tool Steel

- >

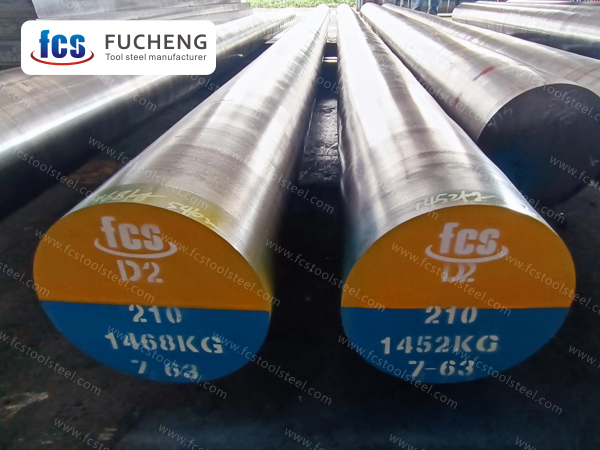

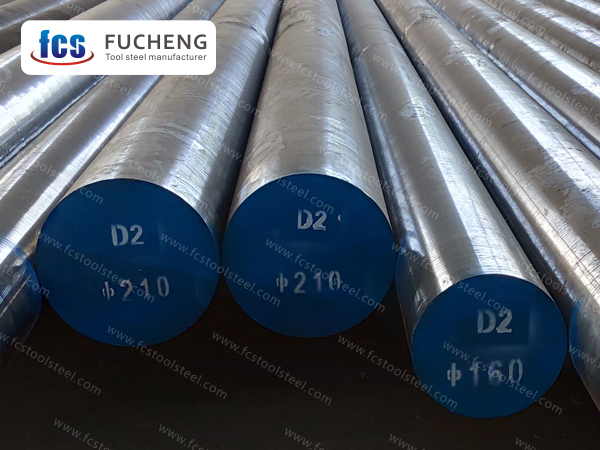

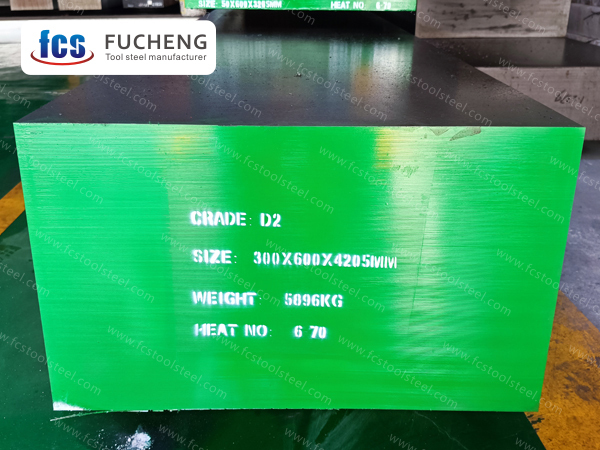

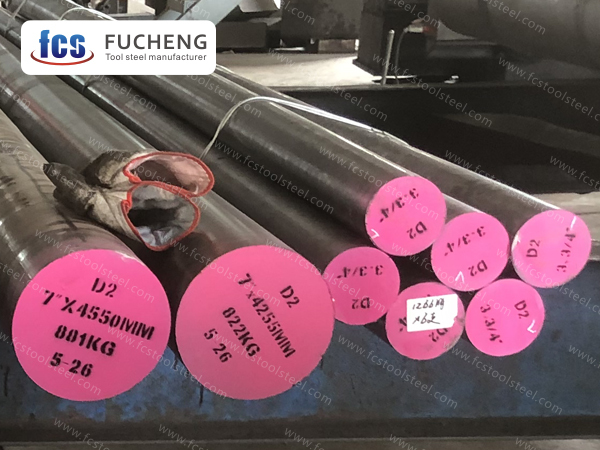

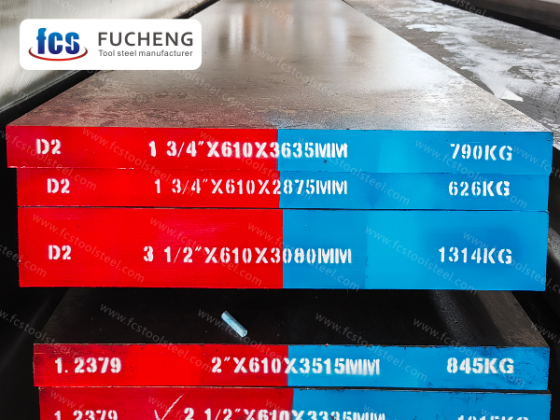

D2 Tool Steel

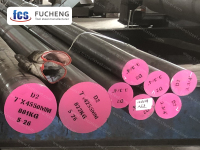

D2 steel is suitable for making all kinds of cold stamping dies with large cross-section and complex shape, as well as cold cutting scissors and thread taking plates; Cold extrusion forming, trimming die, etc

- fucheng steel

- China

- 1 Month

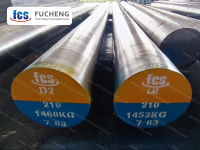

- 2000 Tons/Month

- Information

- Video

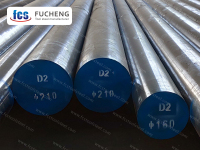

D2 TOOL STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

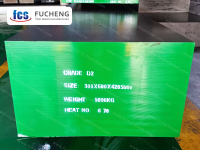

D2 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ASTM | D2 | 1.40~1.60 | ≤0.60 | 0.10~0.60 | 11.00~13.00 | 0.70~1.20 | 0.70~1.10 |

| DIN/W-Nr. | X153CrMo12/1.2379 | 1.45~1.60 | ≤0.60 | 0.10~0.40 | 11.00~13.00 | 0.70~1.00 | 0.70~1.00 |

| JIS | SKD11 | 1.40~1.60 | ≤0.40 | ≤0.40 | 11.00~13.00 | 0.80~1.20 | 0.20~0.50 |

APPLICATION

D2 steel is suitable for making all kinds of cold stamping dies with large cross-section and complex shape, as well as cold cutting scissors and thread taking plates; Cold extrusion forming, trimming die, etc

D2 Steel Heat Treatment Process

Stress relieving annealing

After rough machining of the workpiece, heat it to 600~650 ℃, keep it warm for 2 hours, cool it to 500 ℃ with the furnace, and then air cool it out of the furnace.

quenching

Slowly raise the temperature of the workpiece to 600 ℃, hold it for 20 minutes for secondary preheating, and then rise to 850 ℃ after average temperature. Hold it for another 30 minutes for a second preheating, and then raise the temperature to 1020~1040 ℃, hold it for 25~40 minutes, and discharge it for air cooling.

tempering

After quenching, D2 steel should be immediately tempered and tempered at least twice, with each holding time not less than 2 hours

Attention: Tempering should be carried out in a timely manner after quenching to prevent D2 steel cracking and surface decarburization. Gauges and high-precision molds should be subjected to deep cooling treatment (-70 ℃) and high-temperature tempering should be used to reduce workpiece deformation. The high-temperature tempering temperature is 500~560 ℃, and the hardness is greater than 58HRC. Hardness: annealed, ≤ 255HB, and the indentation diameter is ≥ 3.8mm; Quenching, ≥ 59HRC

D2 steel heat treatment specifications: quenching, 820 ± 15 ℃ preheating, 1000 ± 6 ℃ (salt bath) or 1010 ± 6 ℃ (furnace controlled atmosphere) heating, insulation for 10-20 minutes, air cooling, 200 ± 6 ℃ tempering.