- Home

- >

- Products

- >

- 1.2601 Tool Steel

- >

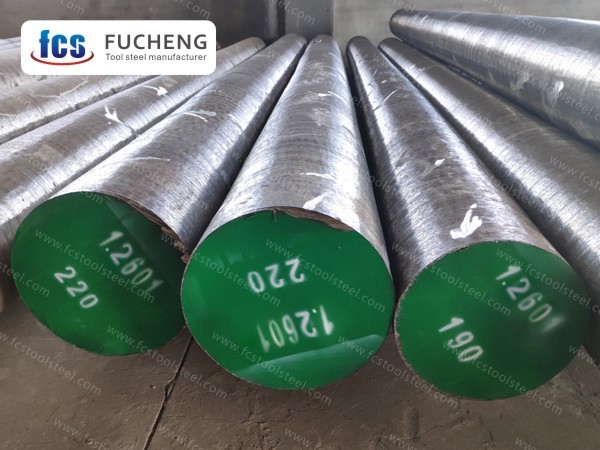

1.2601 Tool Steel

1.2601 is used to manufacture various cold punching dies and tools with large cross-section, complex shape and heavy working conditions, such as punching die, trimming die, edge rolling die, steel plate deep drawing die, circular saw, standard tools and gauges, thread rolling die, etc.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

1.2601 STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

1.2601 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| DIN/W-Nr. | X165CrMoV12/1.2601 | 1.55~1.75 | 0.25~0.40 | 0.20~0.40 | 11.00~12.00 | 0.50~0.70 | 0.10~0.50 |

| GB | Cr12MoV | 1.45~1.70 | ≤0.40 | ≤0.40 | 11.00~12.50 | 0.40~0.60 | 0.15~0.30 |

| ГOСТ | X12MΦ | 1.45~1.65 | 0.10~0.40 | 0.15~0.45 | 11.00~12.50 | 0.40~0.60 | 0.15~0.30 |

APPLICATION

1.2601 is used to manufacture various cold punching dies and tools with large cross-section, complex shape and heavy working conditions, such as punching die, trimming die, edge rolling die, steel plate deep drawing die, circular saw, standard tools and gauges, thread rolling die, etc.

1.2601 STEEL CHARACTERISTICS

1.2601 steel is a high carbon, high chromium ledeburite steel with hardenability, hardenability, strength and toughness, thermal stability, and compressive strength. The steel has excellent micro deformation and comprehensive properties, and has a wide range of adaptability. In addition, it also has high wear resistance, which is 3-4 times higher than ordinary low alloy tool steel, and has the characteristics of small quenching volume deformation.

According to its characteristics, 1.2601 steel is widely used in manufacturing various cold stamping molds and tools with large cross-sectional areas, complex shapes, and heavy working conditions, such as punching dies, trimming dies, rolling dies, steel plate deep drawing dies, circular saws, standard tools and gauges, thread rolling dies, etc. These molds and tools need to have high strength, high hardness, high wear resistance, and good fatigue resistance to ensure their service life and stability.

In addition to the above application fields, 1.2601 steel can also be used to manufacture various cutting tools and blades. Due to their high hardness and wear resistance, these cutting tools can withstand high-speed cutting and heavy load cutting, thereby improving production efficiency and processing quality. In addition, 1.2601 steel can also be used to manufacture various mechanical parts such as bearings and gears to improve its wear resistance and service life.

It should be noted that 1.2601 steel is supplied in an annealed state with a hardness of ≤ 225HBS. This means that heat treatment is required before use to obtain the required hardness and performance. Common heat treatment methods include quenching and tempering. Quenching can achieve high hardness and strength of steel, while tempering can reduce its brittleness, improve its toughness and machinability. Through reasonable heat treatment processes, the performance of steel can be customized according to specific application requirements.