- Home

- >

- Products

- >

- 1.2080 Tool Steel

- >

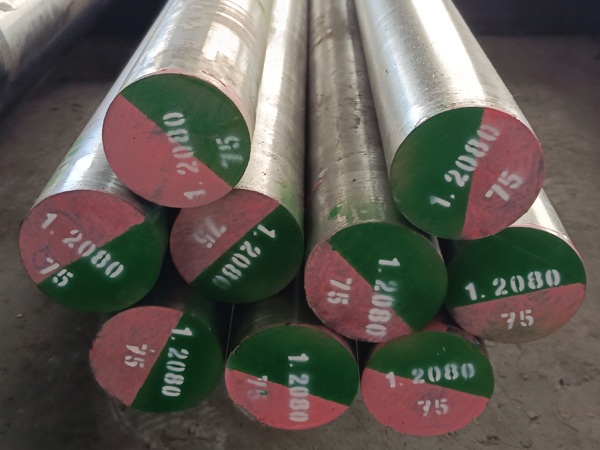

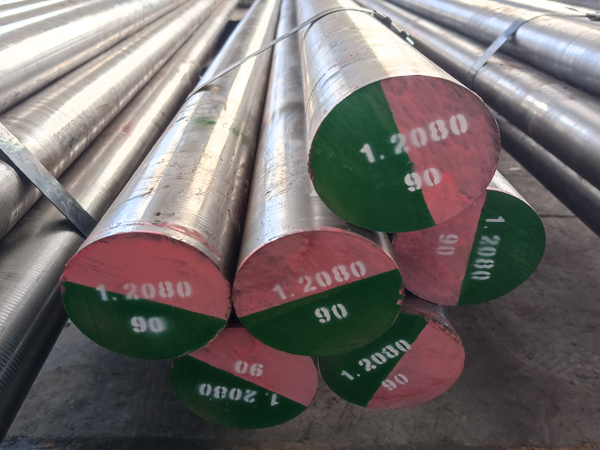

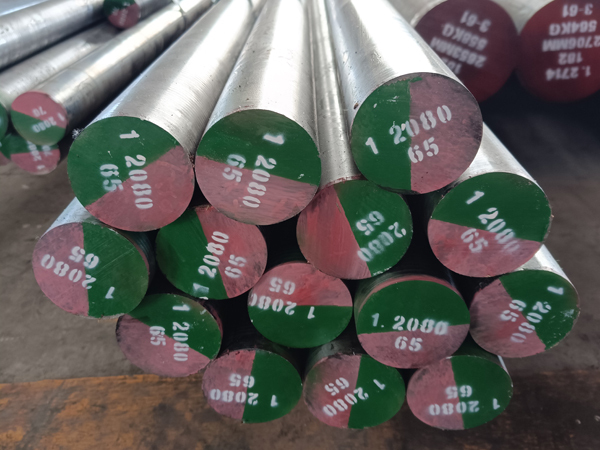

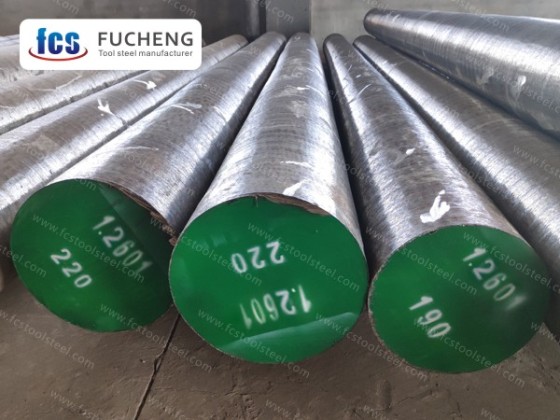

1.2080 Tool Steel

1.2080 steel has high wear resistance and long service life, and is suitable for various cold stamping dies, cold shear blades, thread take-up plates and other complex and possibly deformed tool dies.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

1.2080 TOOL STEEL / x210 cr12 steel

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

1.2080 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||

| C | Si | Mn | Cr | ||

| DIN/W-Nr. | X153CrMo12/1.2080 | 1.9~2.20 | 0.10~0.40 | 0.15~0.45 | 11.0~12.0 |

| ASTM | D3 | 2.0~2.35 | 0.10~0.60 | 0.20~0.60 | 11.0~13.5 |

| JIS | SKD1 | 1.9~2.20 | 0.10~0.60 | 0.20~0.60 | 11.0~13.0 |

APPLICATION

1.2080 steel has high wear resistance and long service life, and is suitable for various cold stamping dies, cold shear blades, thread take-up plates and other complex and possibly deformed tool dies.

Heat Treatment Process of 1.2080 Cold Working Die Steel

Cold working die steel is mainly used for processes such as punching, stretching, bending, cold extrusion, cold heading, wire rolling, and bending of metal or non-metallic materials. Therefore, it is required that the mold has high strength, high wear resistance, and sufficient toughness to ensure its service life. 1.2080 steel is widely used as a universal cold working mold in mass production, and there are usually two heat treatment methods: primary hardening method (low quenching+low recovery) and secondary hardening method (high quenching+high recovery).

The quenching temperature of the one-time hardening method is 1020~1040 degrees, and the tempering temperature can be selected according to the requirements of the mold. Generally, cold stamping molds that require high hardness and wear resistance are tempered at a low temperature of 160~180 degrees, and the hardness after tempering can reach HRC60 or above. For stamping molds that require high hardness and a certain degree of toughness, tempering at 250-270 degrees can be used, and the hardness after tempering can reach HRC58-60. For molds that withstand high impact toughness, high-temperature tempering at 520 degrees can be used, and the hardness after tempering is HRC55-57.

The quenching temperature of the secondary hardness method is 1080-1120 degrees. Due to the presence of a large amount of residual austenite in the quenched steel, the hardness is relatively low (HRC42-45). Through multiple (3-5 times) high-temperature tempering, the residual austenite is transformed into martensite, resulting in secondary hardening. The hardness can be increased to HRC59-64, mainly suitable for mold parts that require red hardness. The disadvantage is poor impact toughness, which affects the multi punch life, so it is not suitable for cold working molds.

Due to the use of low-temperature tempering in the one-time hardening method, although the hardness can reach HRC60 or above, the tempering temperature is relatively low, and the stress relief after quenching is not sufficient. Moreover, in subsequent processing, it is easy to reduce the surface hardness of the workpiece due to grinding heat, which affects its service life.

So the medium temperature quenching+high temperature tempering method is adopted, which is about 1050 degrees Celsius quenching, and the hardness after quenching is at HRC63. Then use high-temperature tempering at temperatures ranging from 500 to 520. Due to the fact that the hardness after secondary hardening and tempering can reach HRC60 or higher, the quenching temperature using this process is lower than that of secondary hardening method. After heat treatment, the mold strength is higher and it also has a certain degree of toughness. Moreover, due to the sufficient stress relief after high-temperature tempering, it is not easy to crack during subsequent wire cutting discharge machining, annealing is not easy during grinding, and the surface can be coated with titanium, which has been applied in production to a certain extent.