- Home

- >

- Products

- >

- 1.2842 Tool Steel

- >

1.2842 Tool Steel

1.2842 steel is suitable for manufacturing precision measuring tools, templates, small stamping/cold pressing/carving/cutting molds, and machine tool screws and other structural components. 1.2842 steel is also commonly used to manufacture cold stamping dies and tools with large cross-sections, complex shapes, and heavy working conditions, such as stamping dies, trimming dies, grinding dies, steel plate deep drawing dies, circular saws, standard tools and gauges, rolling dies, etc.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

- Download

1.2842 TOOL STEEL

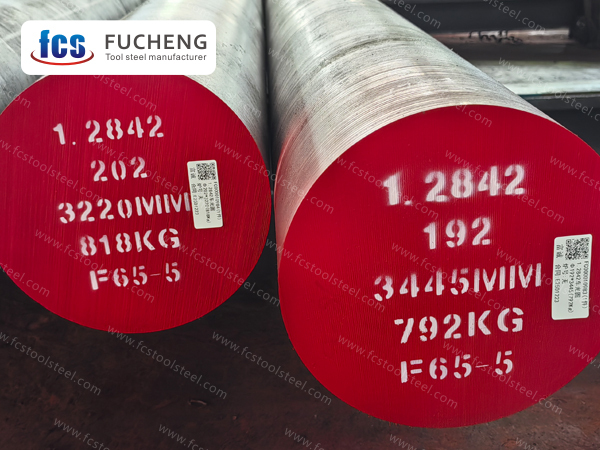

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤212 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

1.2842 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ASTM | O2 | 0.85~0.95 | ≤0.50 | 1.40~1.80 | ≤0.50 | ≤0.30 | ≤0.30 |

| DIN/W-Nr. | 90MnCrV8/1.2842 | 0.85~0.95 | 0.10~0.40 | 1.80~2.20 | 0.20~0.50 | - | - |

| GB | 9Mn2V | 0.85~0.95 | ≤0.40 | 1.70~2.00 | 0.40 | - | 0.10 |

APPLICATION

1.2842 steel, as a high-quality tool steel, is mainly used in the manufacturing of high-precision cold work molds (such as punching dies, stretching dies), wear-resistant cutting tools (turning tools, milling cutters), precision measuring tools (calipers, gauges), and plastic molding molds. Its excellent wear resistance and thermal stability make it particularly suitable for industrial scenarios that require long-term maintenance of dimensional accuracy and cutting edge sharpness. At the same time, its good processing performance also reduces the difficulty of manufacturing complex molds.

1.2842 STEEL CHARACTERISTICS

1.2842 steel is a high carbon and high alloy tool steel widely used in the industrial field due to its excellent comprehensive performance. 1.2842 steel, through special alloy ratios and heat treatment processes, maintains high hardness while also possessing good toughness, making it particularly suitable for manufacturing precision tool components that require high load and wear resistance.

The most prominent feature of 1.2842 steel is its excellent wear resistance. Due to its high proportion of carbon and chromium elements, 1.2842 steel can form a large amount of hard carbides, allowing it to maintain surface integrity under continuous friction and impact conditions, significantly extending the tool's service life. This characteristic makes it an ideal choice for stamping molds and cutting tools.

In terms of thermal stability, 1.2842 steel performs well. Even at higher operating temperatures, the stability of the organizational structure can be maintained, avoiding performance degradation caused by temperature changes. This feature makes it suitable for mold applications that require repeated heating and cooling, such as hot work molds and plastic molding molds.

In addition, 1.2842 steel has good processing performance and hardenability. It can be precision formed through conventional mechanical processing methods and achieve uniform hardness distribution during heat treatment. This feature greatly reduces manufacturing difficulty and cost, making it an economically efficient material choice in the field of tool manufacturing.