- Home

- >

- News

- >

- TOOL STEEL INDUSTRY NEWS

- >

News

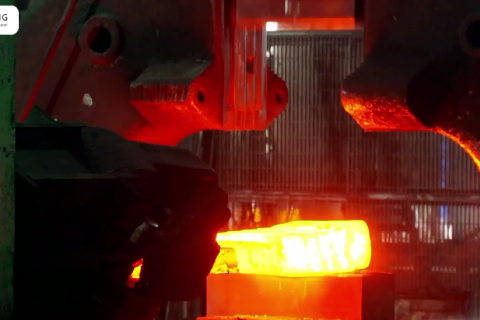

The forging furnace is one of the important equipment in the mechanical processing industry. It may encounter various faults and hidden dangers during use, so maintenance work is critical.

Electric furnaces are widely used for the smelting of non-ferrous metals [mainly used in the smelting of ferrous metal materials such as steel, alloy steel, special steel, cast iron, and the smelting of non-ferrous metal materials such as stainless steel and zinc. It can also be used for the smelting and heating of non-ferrous metals such as copper and aluminum. , heat preservation, and can operate in tandem with the blast furnace.

Steel is an important commodity related to the national economy and people's livelihood, and its price fluctuations are affected by many factors. The following is Main factors affecting steel price changes:

Heat Treatment Deformation and Prevention of Precision Mold

Tool steel is a type of steel that is specifically designed for use in the manufacturing of tool steel, Tool steel are used in the production of various products, including metal parts, plastic components, and even food items. here are several types of tool steel available, each with its own unique properties and advantages.

Based on the following 5 steelmaking-related questions, we give informative answers. Welcome to discuss. 1. How to understand deoxygenation capacity? 2. What is the effect of increasing the size of the inclusion? 3. What is the shape of inclusions in molten steel? 4. What is the effect of molten steel flow on inclusion exclusion? 5. What are the advantages of the carbon pull method?

With the continuous development of industrial manufacturing, the requirements for the performance of mold steel are also increasing. In this context, 1.2083 mold steel stands out among many mold steels due to its excellent performance, providing strong support for the development of related industries.

1.2343 mold steel has attracted widespread attention in the field of mold manufacturing due to its excellent performance. This high alloy steel not only has excellent processing performance and wear resistance, but its strength and toughness at high temperatures make it an ideal choice for many heavy-duty working environments. With the continuous upgrading of industrial demand, the application prospects of 1.2343 mold steel are highly anticipated.

The emergence of 1.2344 mold steel has brought new development opportunities to the mold manufacturing industry. It not only improves the service life and work efficiency of the mold, but also helps to improve the quality of the final product. With the progress of materials science and continuous innovation in manufacturing technology, it is expected that the application of 1.2344 mold steel will become more widespread, which will play a positive role in promoting technological progress and industrial upgrading in related industries.