Multiple Applications of 1.2343 Mold Steel

2024-05-27 16:311.2343 mold steel has attracted widespread attention in the field of mold manufacturing due to its excellent performance. This high alloy steel not only has excellent processing performance and wear resistance, but its strength and toughness at high temperatures make it an ideal choice for many heavy-duty working environments. With the continuous upgrading of industrial demand, the application prospects of 1.2343 mold steel are highly anticipated.

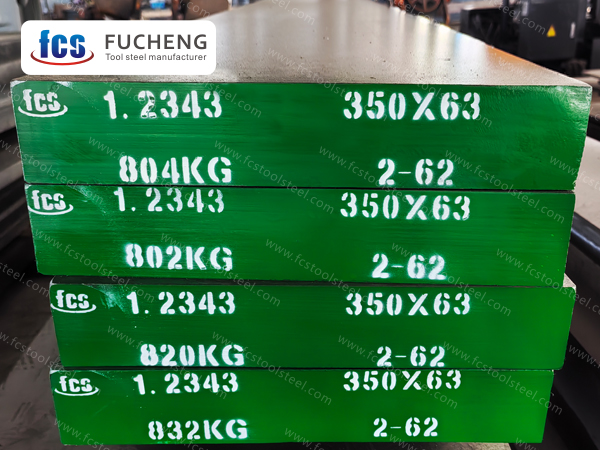

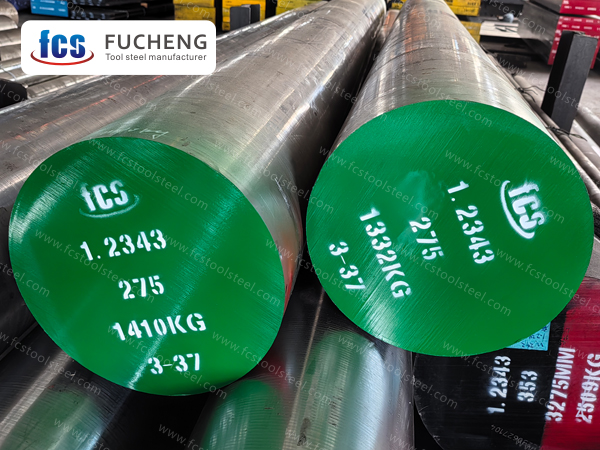

1.2343 mold steel, also known as H11 or SKD6, is a hot work mold steel refined by electroslag remelting (ESR) technology. This steel is known for its uniform material, excellent cutting and polishing properties. 1.2343, which has high thermal fatigue resistance and wear resistance, can maintain small size changes during heat treatment, making it very suitable for the manufacturing of precision molds.

Mainly used for plastic injection molds, die-casting molds, and hot work molds. Due to its high toughness and plasticity, this steel can withstand extreme working conditions such as high pressure and temperature fluctuations, ensuring the long-term stability and efficient performance of the mold. In addition, the good hardenability and isotropy make 1.2343 mold steel perform well in surface treatments such as nitriding, further enhancing its competitiveness in the high-end mold manufacturing field.