Issues that Need Attention in the Maintenance and Repair of Forging Furnaces

2023-11-04 16:54About Forging Furnace

About Forging Furnace

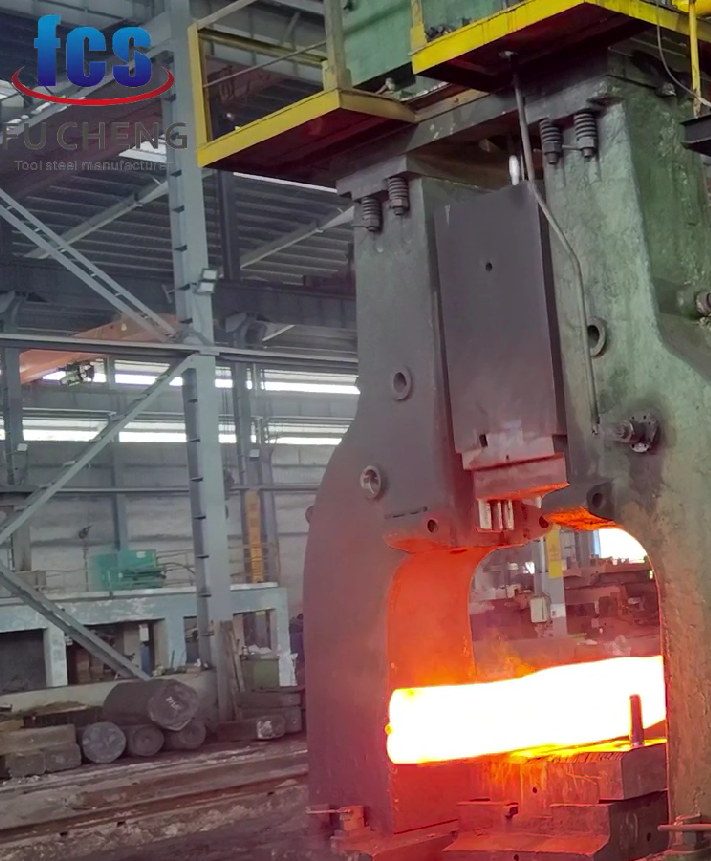

The forging furnace is one of the important equipment in the mechanical processing industry. It may encounter various faults and hidden dangers during use, so maintenance work is critical.

So, what issues need to be paid attention to in the maintenance and repair of forging furnaces? The following will give you a detailed introduction.

What are the common failures during the use of forging furnaces?

Cable damage: The molten steel temperature sensor is connected to the control system by a long cable, so it is susceptible to corrosion in the high-temperature furnace environment, causing cable damage.

Thermal protection relay failure: During the temperature control process, the thermal protection relay is an important safety guarantee. If it fails, it may cause an accident due to excessive temperature.

The electric heating element is burned out: When the electric heating element is working, the temperature and current are very high, and it is prone to short circuit, burnout and other faults.

Impaired mechanical properties: The overall mechanical properties of the furnace are affected by many factors, such as long-term thermal expansion and cooling shrinkage, rust and oxidation, etc., which will cause deformation, cracks, and decline in mechanical properties of the furnace.

What issues need to be paid attention to during maintenance?

1. Regular maintenance: Regular maintenance should be carried out according to the usage requirements, including checking the wear of each component, confirming the accuracy of each sensor and replacing damaged components.

2. Keep it clean: During use, a lot of dust and dirt will accumulate in the forging furnace. These impurities will not only contaminate the castings, but also affect the heating efficiency and safety of the forging furnace. Therefore, be sure to clean it regularly and keep it clean.

3. Strictly control the entry and exit of the crucible and pouring materials: The crucible of the forging furnace is filled with molten metal. If due to improper use, high temperature operation, etc., the crucible breaks or there is a problem with the entry and exit of the pouring materials, it may cause casualties.

4. Prevent oxidation: At high temperatures, metal materials in the forging furnace are easily oxidized, accelerating the aging and corrosion of the equipment, resulting in short life of the equipment. Therefore, effective measures must be taken to prevent oxidation and slow down equipment wear.

5. Safe operation: Operators need to receive professional forging furnace operation training and understand their job responsibilities, safety regulations and emergency measures to ensure a safe working environment and a stable production process.

In short, the maintenance of forging furnaces is very important, and must be carried out in strict accordance with the requirements, and detailed inspection procedures must be developed to ensure normal operation of the equipment and safe production.