H13 Tool Steel | 1.2344 | X40CrMoV5-1 | SKD61 Hot Work Steel

H13 hot working die steel. It has excellent machinability and polishing performance, high toughness and plasticity, good high and low temperature wear resistance, high temperature fatigue and heat resistance.

H13 tool steel can be used for die forging hammer forging die, aluminum alloy die casting die, hot extrusion die, high-speed precision forging die and forging press die, etc.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

H13 Steel

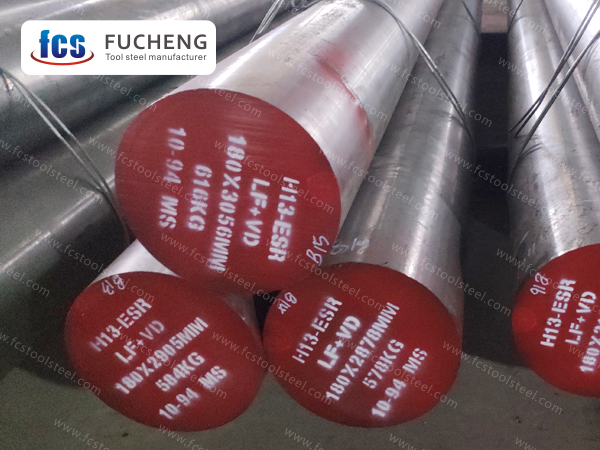

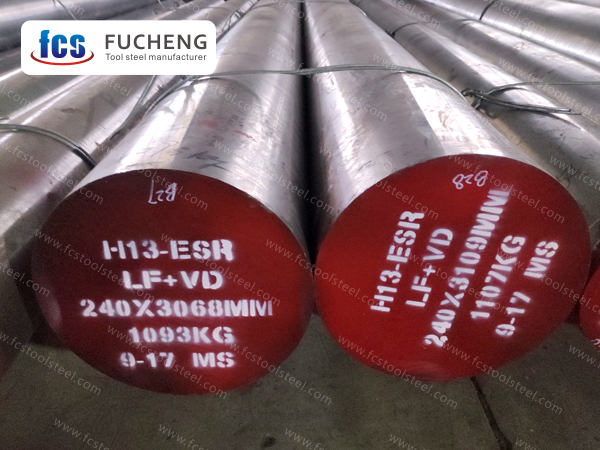

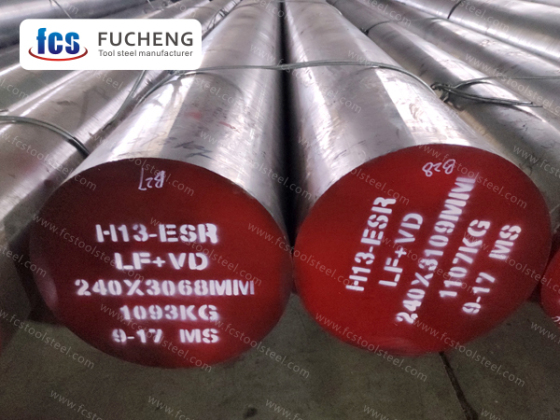

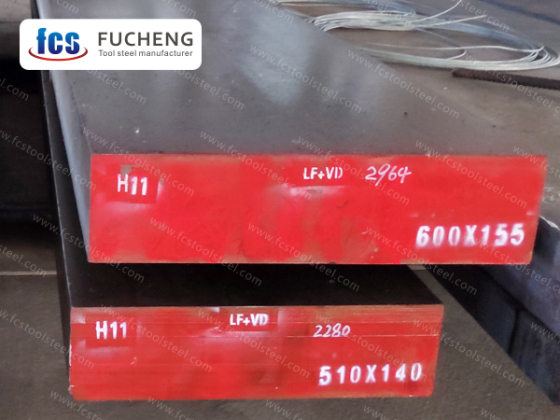

| Smelting and Manufacture Method: | LF+VD+ESR+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤235 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

H13 Steel GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ASTM | H13 | 0.32~0.45 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.75 | 0.80~1.20 |

| DIN/W-Nr. | X40CrMoV5-1/1.2344 | 0.37~0.42 | 0.90~1.20 | 0.30~0.50 | 4.80~5.50 | 1.20~1.50 | 0.90~1.10 |

| JIS | SKD61 | 0.35~0.42 | 0.80~1.20 | 0.25~0.50 | 4.80~5.50 | 1.00~1.50 | 0.80~1.15 |

APPLICATION

H13 tool steel can be used for die forging hammer forging die, aluminum alloy die casting die, hot extrusion die, high-speed precision forging die and forging press die, etc.

H13 Steel Characteristics

H13 steel is a type of mold steel with characteristics including high toughness and ductility, excellent polishing performance, and easy cutting. In addition, it also has stable and excellent processing and polishing properties, exhibiting good wear resistance in both high and low temperature environments.

The physical properties of H13 steel are also excellent, such as a density of 7.31g/cm ³, The elastic modulus is 212000MPa at 20 ° C. At the same time, it has good high-temperature strength and thermal fatigue resistance, and good hardenability, which means that it can quickly achieve the required hardness during the quenching process. Another noteworthy feature is that its heat treatment size changes very little, which is particularly important for the manufacturing of precision components.

This type of steel is particularly suitable for cold extrusion and die casting mold manufacturing of alloys such as aluminum and zinc. Due to its excellent heat resistance and high-temperature toughness, it is also suitable for working conditions in high-temperature environments. H13 steel exhibits excellent performance in terms of hardness, strength, and corrosion resistance, making it widely used in many industrial fields.

H13 steel is widely used in mold manufacturing. Due to its high toughness and ductility, the mold is less prone to fracture or deformation during use, thus ensuring its service life and accuracy. Meanwhile, its excellent polishing performance results in a good surface finish of the mold, reducing surface defects and defects, and improving the quality and appearance of the product. In addition, H13 steel also has good machinability, making the processing of molds easier and faster.

H13 steel also has important applications in automotive manufacturing. Due to the need for various components of automobiles to withstand high temperature and high pressure working environments, it is necessary to use materials with high strength and wear resistance to manufacture these components. The high toughness and wear resistance of H13 steel make it one of the ideal choices for manufacturing automotive engine parts. In addition, H13 steel also has good corrosion resistance and can maintain its performance and lifespan in harsh automotive working environments.

H13 steel also has important applications in the aerospace field. Due to the extreme temperature and pressure conditions that aerospace equipment needs to withstand, it is necessary to use materials with high strength and wear resistance to manufacture these equipment. The high toughness and wear resistance of H13 steel make it one of the ideal choices for manufacturing aerospace equipment. In addition, H13 steel also has good corrosion resistance and can maintain its performance and lifespan in harsh aerospace working environments.