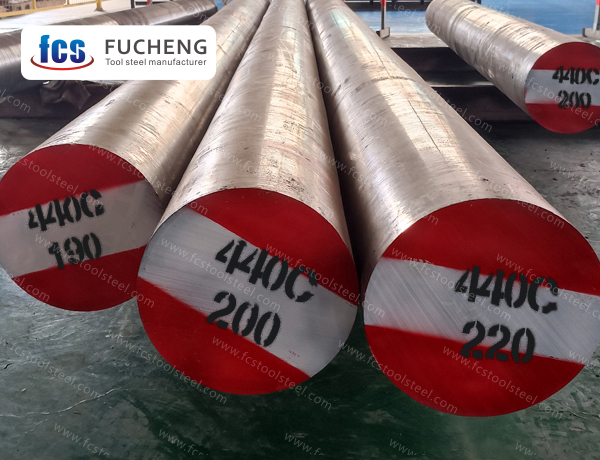

440C Plastic Mould Steel

440C steel is a kind of martensitic stainless steel. It has strong rust resistance and is high-quality stainless steel.

440C steel is mainly used to manufacture bearing parts working in corrosive environment and unlubricated strong oxidation atmosphere. 440C steel has good dimensional stability at high temperature, so it can also be used as corrosion-resistant high temperature bearing steel. In addition, it can also be used to manufacture high-quality knives, such as medical scalpels, scissors, nozzles, bearings, etc.

- Fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

440C STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

440C STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | |||||

| C | Si | Mn | Cr | Mo | ||

| ASTM | 440C | 0.95~1.20 | ≤1.00 | ≤1.00 | 16.00~18.00 | ≤0.75 |

| GB | 9Cr18Mo | 0.95~1.10 | ≤0.80 | ≤0.80 | 16.00~18.00 | 0.40~0.70 |

APPLICATION

440C steel is mainly used to manufacture bearing parts working in corrosive environment and unlubricated strong oxidation atmosphere. 440C steel has good dimensional stability at high temperature, so it can also be used as corrosion-resistant high temperature bearing steel. In addition, it can also be used to manufacture high-quality knives, such as medical scalpels, scissors, nozzles, bearings, etc.

440C STEEL CHARACTERISTICS

440C steel is a high carbon and high chromium martensitic stainless steel with good corrosion resistance, wear resistance, and hardness. It is commonly used in the manufacturing of mechanical parts such as cutting tools, bearings, valves, pumps, as well as in the fields of medical equipment, aerospace, and automotive components.

The chemical composition of 440C steel includes elements such as carbon, chromium, molybdenum, manganese, silicon, phosphorus, and sulfur. Among them, the carbon content is relatively high, usually between 0.95% and 1.20%, which makes 440C steel have high hardness and wear resistance. The chromium content is also very high, usually between 16.0% and 18.0%, which makes 440C steel have good corrosion resistance.

The mechanical properties of 440C steel include yield strength, tensile strength, elongation, and hardness. Its yield strength is usually above 800MPa, tensile strength is usually above 1000MPa, elongation is usually between 10% and 15%, and hardness is usually between 58HRC and 62HRC.

The corrosion resistance of 440C steel mainly depends on its chromium content. Chromium is an element that can form a dense oxide film, which can prevent further corrosion of the steel surface. 440C steel has a high chromium content, therefore it has good corrosion resistance and can be used for a long time in humid and corrosive environments.

The wear resistance of 440C steel is also good, due to its high carbon content and hardness. The hardness of 440C steel is usually between 58HRC and 62HRC, which makes it resistant to wear and scratches and suitable for manufacturing parts that require high wear resistance such as cutting tools and bearings.

It should be noted that the processing performance of 440C steel is poor, and appropriate processing techniques and tools need to be used for processing. Meanwhile, due to its high carbon content, 440C steel is prone to cracking during welding, and appropriate welding processes and materials need to be used to avoid this situation.