- Home

- >

- Products

- >

- 420SS Tool Steel

- >

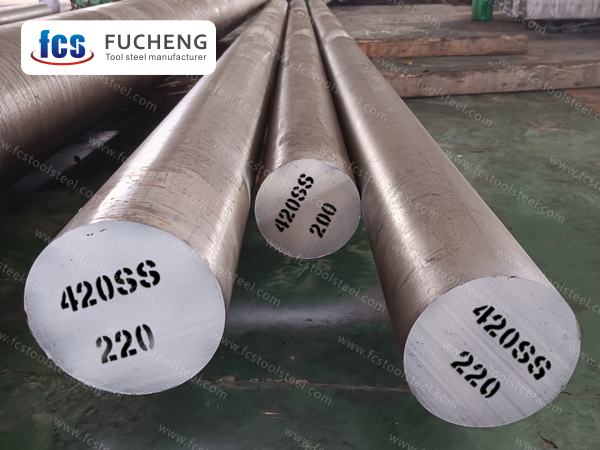

420SS Tool Steel

420SS steel is suitable for making hot oil pumps, valve plates, valve bearings, medical devices, springs, cutting tools, nozzles, valve seats and other parts with high hardness and high wear resistance.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

420SS TOOL STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤225 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

420SS STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

420SS STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||

| C | Si | Mn | Cr | ||

| ASTM | 420SS | 0.30~0.40 | ≤1.00 | ≤1.25 | 12.0~14.0 |

| DIN/W-Nr. | X42Cr13/1.2083 | 0.38~0.45 | ≤1.00 | ≤1.00 | 12.5~13.5 |

| JIS | SUS420J2 | 0.26~0.40 | ≤1.00 | ≤1.00 | 12.0~14.0 |

APPLICATION

420ss steel is suitable for making hot oil pumps, valve plates, valve bearings, medical devices, springs, cutting tools, nozzles, valve seats and other parts with high hardness and high wear resistance.

420SS STEEL CHARACTERISTICS

420SS steel, also known as SUS420 stainless steel, has the characteristics of high hardness and good corrosion resistance after quenching. Therefore, this material is widely used in manufacturing products such as cutting tools, nozzles, and valve seats. At the same time, for some parts that need to withstand significant wear, such as hot oil pumps, valve discs, valve bearings, etc., the hardness and wear resistance of 420SS steel also make it an ideal material for making such parts.

Firstly, let's take a look at the basic characteristics of 420SS steel. 420SS steel is a martensitic stainless steel with a carbon content of approximately 0.3-0.6% and a chromium content of approximately 13%, which allows it to achieve higher hardness after quenching. In addition, 420SS steel also contains a small amount of elements such as nickel and molybdenum, which can improve the strength and corrosion resistance of the steel.

In terms of hardness, after quenching treatment, the hardness of 420SS steel can reach HRC58-62, which makes it have excellent performance in making products such as cutting tools and nozzles. For example, when making cutting tools, high hardness can make them sharper and more wear-resistant, thereby extending their service life. When making nozzles, high hardness can make them more wear-resistant and resistant to high temperatures, thereby improving their service life.

In terms of corrosion resistance, 420SS steel has good corrosion resistance due to its chromium content. Chromium can combine with oxygen to form a dense oxide film, which can prevent further oxidation of the steel and protect it from corrosion. In addition, 420SS steel also contains a small amount of nickel element, which can improve the corrosion resistance and heat resistance of the steel.

In addition to hardness and corrosion resistance, 420SS steel also has good polishing performance and weldability. In terms of polishing performance, 420SS steel can be polished to make its surface smooth and bright, thereby improving the appearance quality of the product. In terms of weldability, 420SS steel can connect multiple parts together through welding processes, thereby facilitating product production and maintenance.