- Home

- >

- Products

- >

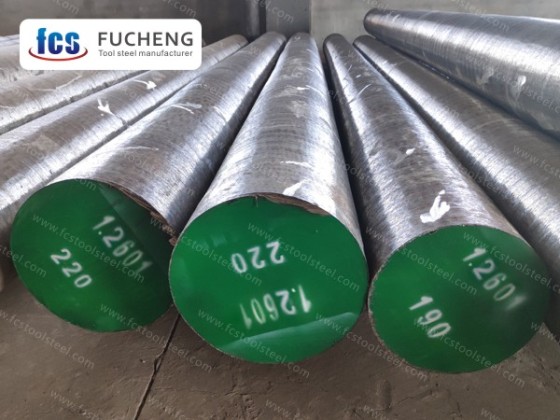

- 1.2436 Tool Steel

- >

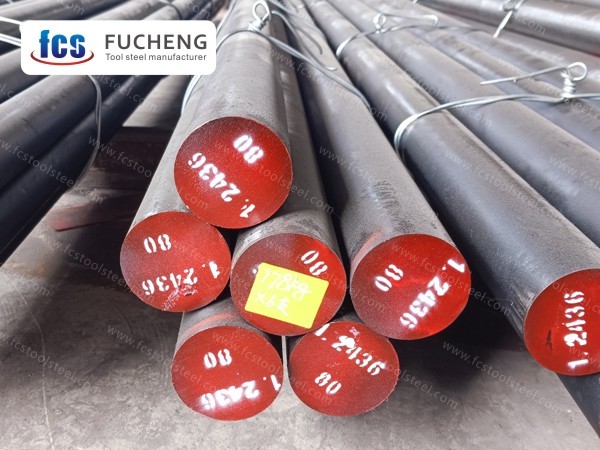

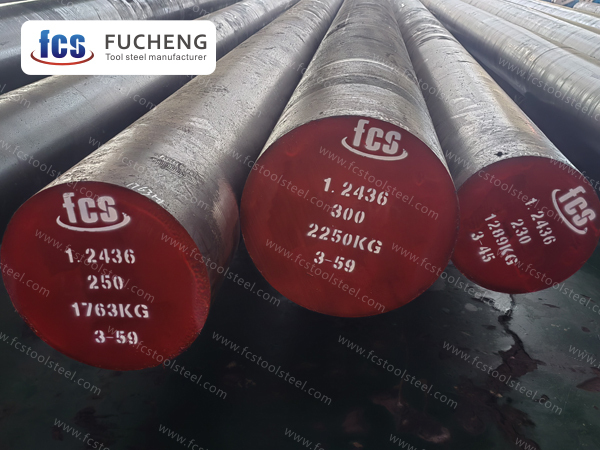

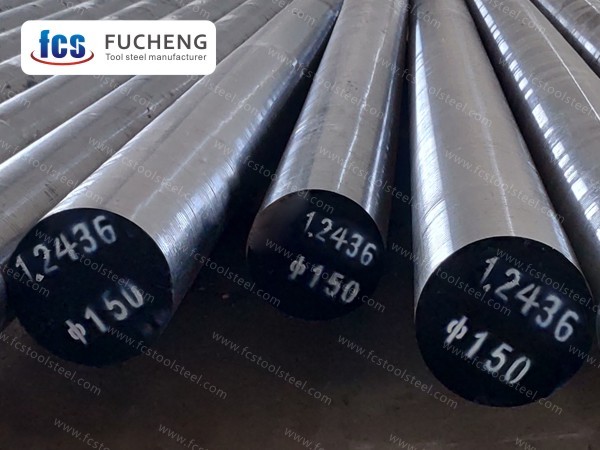

1.2436 Tool Steel

1.2436 steel is suitable for medium load stamping die, stamping stainless steel, copper, silicon, aluminum, etc.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

1.2436 STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

1.2436 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | |||||

| C | Si | Mn | Cr | W | ||

| DIN/W-Nr. | X210CrW12/1.2436 | 2.00~2.25 | 0.10~0.40 | 0.15~0.45 | 11.00~12.00 | 0.60~0.80 |

| GB | Cr12W | 2.00~2.30 | 0.10~0.40 | 0.30~0.6 | 11.00~13.00 | 0.60~0.80 |

| ASTM | D6 | 2.00~2.20 | 0.35~0.50 | 0.20~0.40 | 11.50~12.50 | 0.60~0.90 |

| JIS | SKD2 | 2.00~2.30 | 0.10~0.40 | 0.30~0.60 | 11.00~13.00 | 0.60~0.80 |

APPLICATION

1.2436 steel is suitable for medium load stamping die, stamping stainless steel, copper, silicon, aluminum, etc.

1.2436 STEEL CHARACTERISTICS

1.2436 steel is a type of mold steel with special characteristics. It is widely used in many fields, thanks to the extremely high wear resistance and blade retention ability of 1.2436 steel. This allows it to maintain good performance in heavy-duty working environments such as extrusion molds and hot casting molds. In these applications, molds often need to withstand high temperature, high pressure, and high wear environments. The high hardness and wear resistance of 1.2436 steel enable it to maintain stable performance in such environments, extending the service life of the mold. In addition, this type of steel is particularly suitable for punching materials such as stainless steel, copper, silicon, and aluminum. These materials generate a large amount of heat and wear during the processing, and the high wear resistance of 1.2436 steel enables it to effectively resist these effects, ensuring the accuracy and lifespan of the mold.

1.2436 steel, as a high carbon and high chromium tool steel, has very high hardness and wear resistance. This makes it widely used in cutting processing. In cutting, the cutting tool needs to withstand the high temperature and high pressure generated by high-speed cutting, while also engaging in intense friction with the workpiece. This requires the tool to have sufficient hardness and wear resistance to resist these effects. The high hardness and wear resistance of 1.2436 steel make it an ideal cutting tool material. In addition, it also belongs to the category of cold working mold steel, which has high strength and good hardenability. This makes it have good performance in manufacturing cold working molds and can meet various complex processing needs.

However, although 1.2436 steel has many advantages, it also has some shortcomings. For example, its impact toughness is poor. This means that there may be problems during impact operations. Impact toughness refers to the fracture resistance of a material under impact loads. Due to the poor impact toughness of 1.2436 steel, fracture or damage may occur during impact operations. To solve this problem, it is usually necessary to take some measures in the design and manufacturing process to improve the impact toughness of materials, such as through overheating treatment, surface treatment, etc. to improve the mechanical properties of materials.