- Home

- >

- Products

- >

- SKD11 Tool Steel

- >

SKD11 Tool Steel

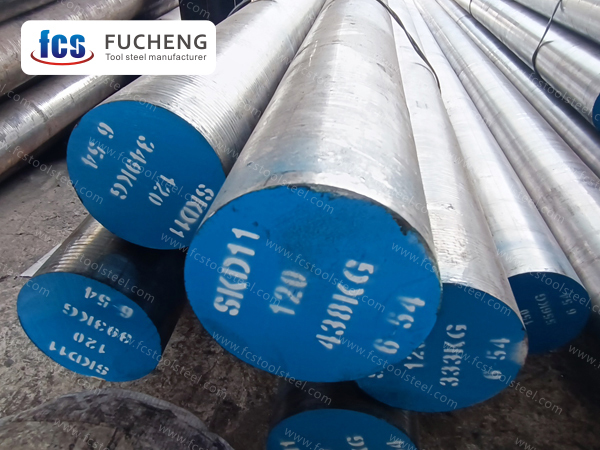

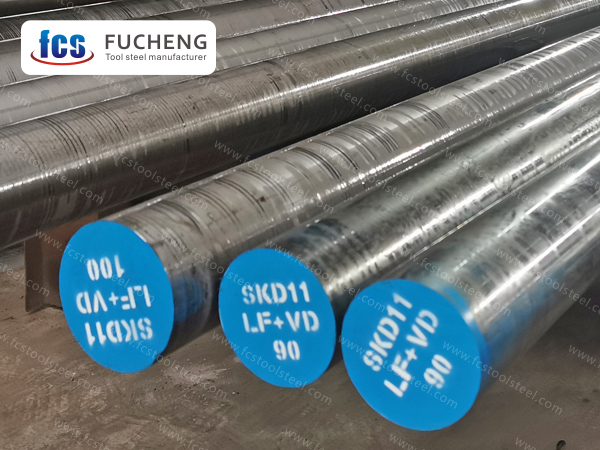

SKD11 tool steel is a high wear-resistant cold working die steel, which belongs to air hardened tool steel. It can be used to manufacture cold working die steel with large section, complex shape, large impact force and high wear resistance.

SKD11 tool steel is suitable for complex and possibly deformed tool steel, all kinds of cold stamping dies with high wear resistance and long life, cold shear blades and wire rubbing plates; Cold extrusion forming, drawing die, beer stainless steel sheet and blanking die for high hardness materials, etc.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

SKD11 TOOL STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

SKD11 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| JIS | SKD11 | 1.40~1.60 | ≤0.40 | ≤0.60 | 11.00~13.00 | 0.80~1.20 | 0.20~0.50 |

| ASTM | D2 | 1.40~1.60 | ≤0.60 | ≤0.60 | 11.00~13.00 | 0.70~1.20 | 0.50~1.10 |

| DIN/W-Nr. | X153CrMo12/1.2379 | 1.45~1.60 | ≤0.60 | 0.10~0.40 | 11.00~13.00 | 0.70~1.00 | 0.70~1.00 |

APPLICATION

SKD11 tool steel is suitable for complex and possibly deformed tool steel, all kinds of cold stamping dies with high wear resistance and long life, cold shear blades and wire rubbing plates; Cold extrusion forming, drawing die, beer stainless steel sheet and blanking die for high hardness materials, etc.

SKD11 STEEL CHARACTERISTICS

SKD11 steel is a universal cold working die steel with high wear resistance and toughness, which is widely used in the cold extrusion, cold heading, and stamping processing of various metal parts. Due to its excellent performance, SKD11 steel has been widely used in the manufacturing industry. The following are the characteristics of SKD11 steel:

1. High hardness and wear resistance

The hardness of SKD11 tool steel can reach 60-62HRC, which is incomparable to other ordinary steels. In addition, SKD11 also has excellent wear resistance and can resist many common forms of wear, such as abrasive wear, adhesive wear, and fatigue wear. This allows it to maintain a long service life in various harsh working environments.

2. High toughness and ductility

Although SKD11 tool steel has high hardness, it also has excellent toughness and ductility. When subjected to external forces, SKD11 can absorb a large amount of energy, thereby reducing the formation and propagation of cracks. This feature enables SKD11 to maintain stability and reliability under high pressure and impact loads.

3. Good heat treatment performance

SKD11 tool steel can change its physical and mechanical properties through appropriate heat treatment. For example, by quenching and tempering, the hardness, strength, and toughness of SKD11 can be adjusted to adapt to different working conditions. In addition, the heat treatment process of SKD11 has a relatively small impact on deformation, which helps to maintain its dimensional accuracy and surface quality.

4. Good cutting performance

SKD11 tool steel has good machinability and can be processed using conventional cutting tools. In addition, SKD11 has a higher cutting speed, which can improve production efficiency. Therefore, SKD11 is suitable for various cutting methods, such as turning, milling, drilling, and grinding.

5. Good corrosion resistance

SKD11 tool steel has good corrosion resistance and can resist many common corrosive media, such as water, acid, and alkali. This enables SKD11 to maintain good stability and reliability in various harsh working environments.

In short, SKD11 steel is a very excellent cold work mold steel material, which has advantages such as excellent wear resistance, good hardenability, high toughness and strength, and easy processing. It has been widely used in the manufacturing industry, especially in the fields of automotive parts, aerospace devices, electronic devices, etc.