- Home

- >

- Products

- >

- SKD1 Tool Steel

- >

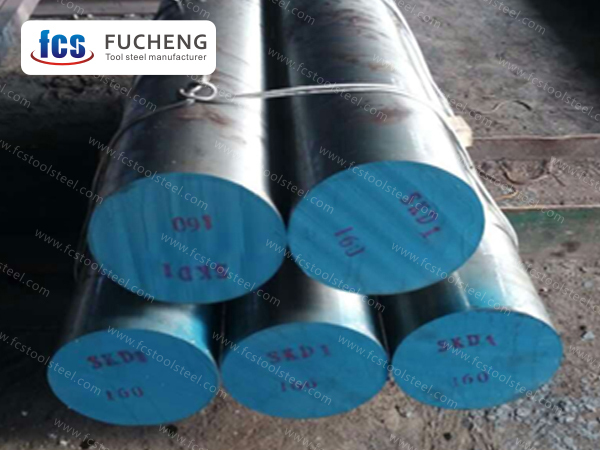

SKD1 Tool Steel

SKD1 steel is often used for cold stamping dies, concave convex dies, drawing dies, rolling dies, cold extrusion dies and other dies with high wear resistance and low impact load.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

SKD1 TOOL STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

SKD1 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

SKD1 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||

| C | Si | Mn | Cr | ||

| JIS | SKD1 | 1.9~2.20 | 0.10~0.60 | 0.20~0.60 | 11.0~13.0 |

| ASTM | D3 | 2.0~2.35 | 0.10~0.60 | 0.20~0.60 | 11.0~13.5 |

| DIN/W-Nr. | X153CrMo12/1.2080 | 1.9~2.20 | 0.10~0.40 | 0.15~0.45 | 11.0~12.0 |

APPLICATION

SKD1 steel is often used for cold stamping dies, concave convex dies, drawing dies, rolling dies, cold extrusion dies and other dies with high wear resistance and low impact load.

SKD1 steel characteristics

SKD1 steel is a high carbon, high chromium type of cold working mold steel, which has characteristics such as high strength, good hardenability, and good wear resistance. It has superior wear resistance and stable heat treatment effect, making it particularly outstanding in manufacturing high-precision and high wear resistant molds. In addition, it has high hardness, suitable for electric candle treatment, strong acid and alkali resistance, and is an excellent choice for long-term production without deformation.

However, despite its many advantages, SKD1 steel has poor impact toughness and can hardly withstand large impact loads, making it prone to brittle cracking and the formation of non-uniform eutectic carbides.

SKD1 steel has a wide range of applications, especially in fields such as automobiles, electronics, and mechanical manufacturing. For example, in the automotive manufacturing industry, SKD1 steel is widely used in the manufacturing of automotive components, such as engine parts, chassis parts, body structural parts, etc. These components need to have high strength, wear resistance, and precision, and SKD1 steel precisely meets these requirements.

In the field of electronics and electrical appliances, SKD1 steel is also widely used. For example, in the production process of electronic products such as mobile phones and computers, a large number of precision molds are required. These molds need to have high precision, high wear resistance, and high stability, and SKD1 steel precisely meets these requirements.

In the field of mechanical manufacturing, SKD1 steel is also widely used. For example, in the manufacturing process of machine tools, a large number of cutting tools and molds need to be used. These tools need to have high strength, wear resistance, and precision, and SKD1 steel precisely meets these requirements.

In addition, SKD1 steel is widely used in other fields, such as aerospace, energy, construction, etc. In these fields, SKD1 steel is used to manufacture various high-precision and wear-resistant tools and components.