- Home

- >

- Products

- >

- 1.2767 Tool Steel

- >

1.2767 Tool Steel

1.2767 steel has good wear resistance, high toughness, high hardness, high compressive strength, excellent dimensional stability, excellent corrosion resistance, good polishing and pin cutting performance, and easy to achieve mirror effect. Good hardenability, air cooling hardening, good machining performance.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

1.2767 TOOL STEEL

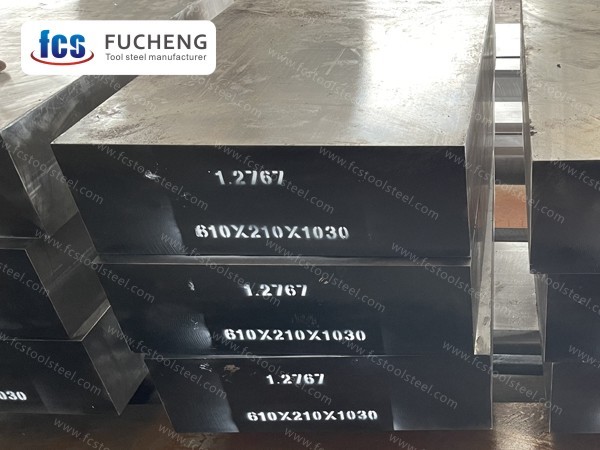

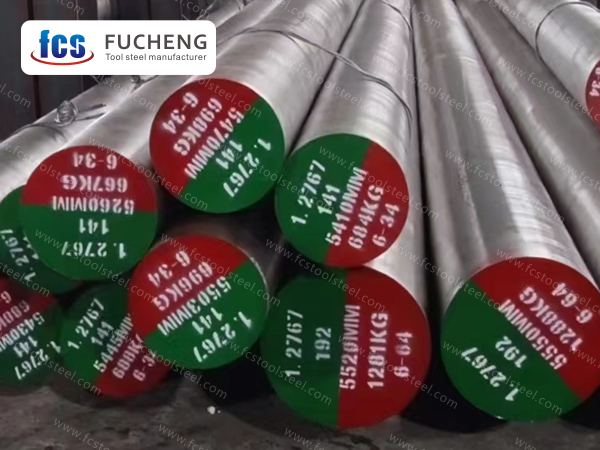

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤260 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

1.2767 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | |||||||

| C | Si | Mn | Cr | Mo | Ni | |||

| DIN/W-Nr. | X45NiCrMo4/1.2767 | 0.40~0.50 | 0.10~0.40 | 0.15~0.45 | 1.20~1.50 | 0.15~0.35 | 3.80~4.30 | |

APPLICATION

1.2767 is applicable to cold forming tools such as extrusion dies, and is also widely used in various cutting tools, cutter dies and punch dies, high wear-resistant plastic molds and screws.

1.2767 Steel Characteristics

1.2767 steel has the characteristics of good wear resistance, high toughness, high hardness, and high compressive strength. It has excellent dimensional stability and excellent corrosion resistance. In addition, this steel has good polishing and cutting performance, making it easy to achieve a mirror effect.

The hardenability of 1.2767 steel is excellent and can be hardened by air cooling and machined. After austenitizing treatment, coarse pearlite structure will be formed during slow cooling, which can reduce the hardness to 210HBS. However, due to its special properties during the transformation of austenite and pearlite, conventional spheroidizing annealing is difficult to soften it. However, high temperature heating can reduce hardness, and the slow cooling process after isothermal insulation can completely change the organizational structure. The austenitizing temperature is 860 ℃, and the isothermal holding temperature is 640 ℃.

For the heat treatment of 1.2767 steel, the hardness requirement is generally between 50 and 54HRC. In addition, under normal conditions without adding water, its brightness can reach 90% and it has good polishing performance.

In addition, 1.2767 steel has a uniform structure, fine texture, and smaller grain size. It has good thermal cutting performance and can be subjected to quenching and high-temperature tempering treatment. Due to its excellent wear resistance, it can withstand long periods of high load work. In addition, 1.2767 steel also has excellent impact resistance, high yield strength, and toughness.

Due to its multifaceted advantages, 1.2767 steel has a wide range of applications and can manufacture high-quality complex molds, tools, and parts. It is particularly suitable for the manufacturing of punch press stamping molds because its high hardness and toughness enable it to withstand high stress and severe impact cyclic loads, and has characteristics of fatigue resistance and fracture resistance.