NAK80 plastic mold steel | P21 | 10Ni3MnCuAl Mold Steel

NAK80 plastic tool steel has good comprehensive mechanical properties, high hardenability and good polishing properties.

NAK80 plastic tool steel is suitable for high-efficiency blanking die, punching die and embossing die, all kinds of scissors, inlaid blade, woodworking blade, thread rolling die and wear-resistant slider, cold heading die, thermosetting resin forming die, deep drawing forming die and cold extrusion die.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

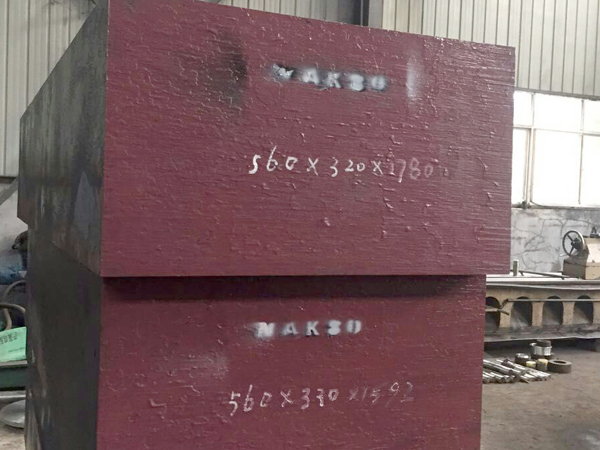

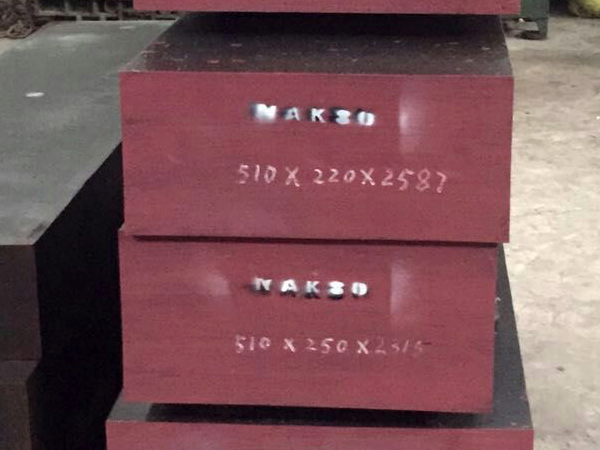

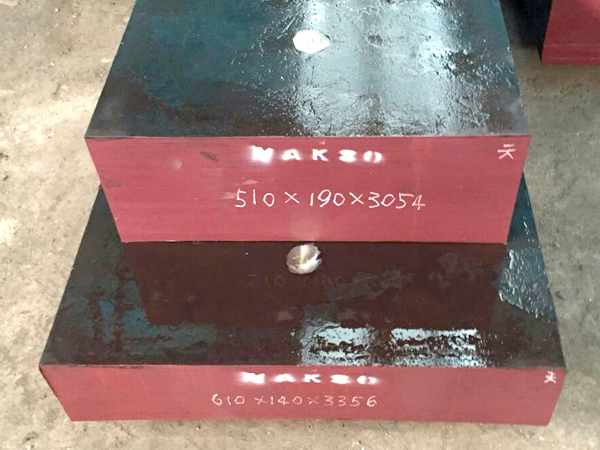

NAK80 PLASTIC MOLD STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤43 HRC |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

NAK80 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||||

| C | Si | Mn | Cr | Mo | W | Al | Cu | ||

| JIS | NAK80 | 0.15 | 0.30 | 0.15 | 0.30 | 0.30 | 0.30 | 1.10 | 1.00 |

APPLICATION

NAK80 plastic tool steel is suitable for high-efficiency blanking die, punching die and embossing die, all kinds of scissors, inlaid blade, woodworking blade, thread rolling die and wear-resistant slider, cold heading die, thermosetting resin forming die, deep drawing forming die and cold extrusion die.

Characteristics of NAK80 plastic mold steel:

1. High hardness and wear resistance

The factory hardness of NAK80 plastic mold steel is about HRC 37-43, and it can be used directly without heat treatment.

Suitable for manufacturing high-precision wear-resistant molds.

2. Excellent polishing performance

NAK80 plastic mold steel has a uniform and delicate structure, and can achieve a mirror effect after polishing, making it suitable for molds with high surface requirements.

3. Good processing performance

The pre hardened state of NAK80 plastic mold steel is still easy to cut, reducing processing difficulty and cost.

4. Corrosion resistance

NAK80 plastic mold steel has certain corrosion resistance and is suitable for humid or corrosive environments.

5. Dimensional stability

NAK80 plastic mold steel has minimal deformation after heat treatment and is suitable for high-precision mold manufacturing.

6. Solderability

NAK80 plastic mold steel has good welding performance and is easy to maintain and modify molds.