- Home

- >

- Products

- >

- M2 HIGH SPEED STEEL

- >

M2 HIGH SPEED STEEL

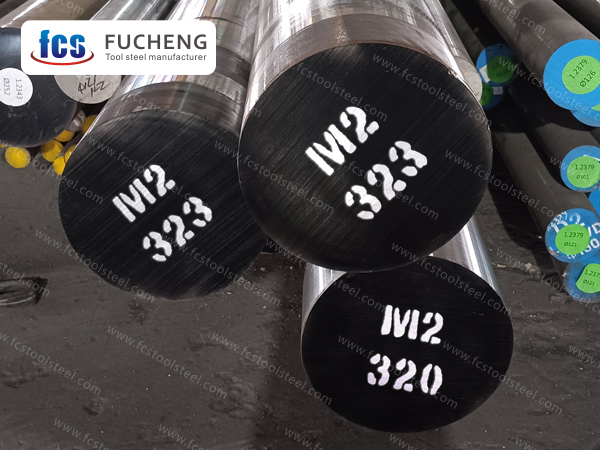

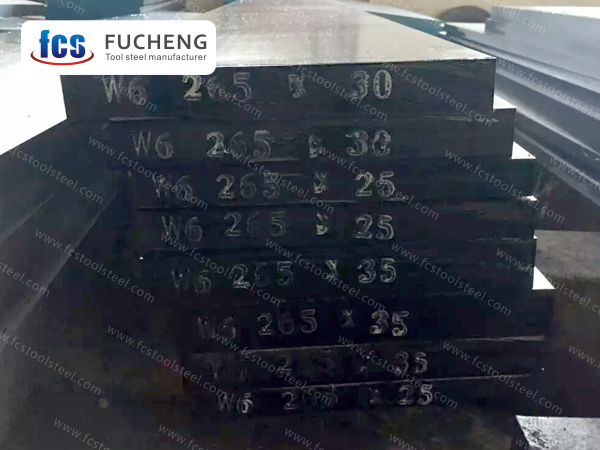

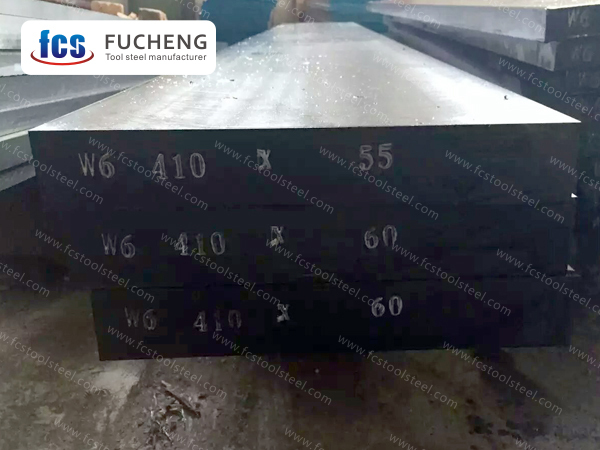

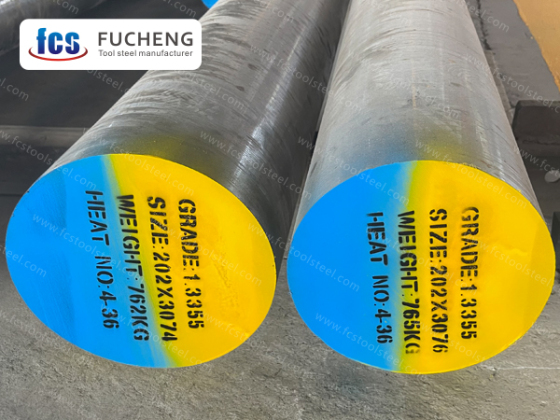

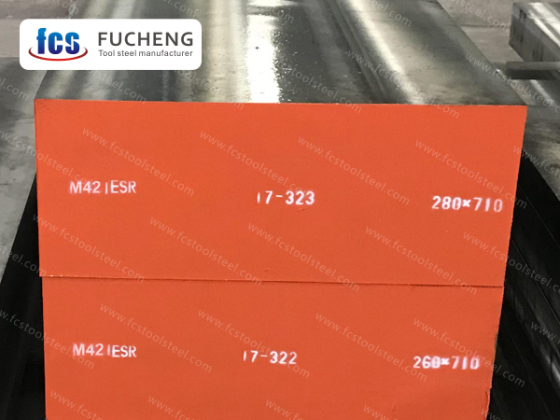

M2 is a kind of tungsten molybdenum high speed steel with good hardness and wear resistance. It is mostly used to make cutting tools for cutting difficult materials.

M2 high speed steel is suitable for dies bearing vibration and impact loads: deep drawing dies, punching dies, metal cutting blades, cold heading and extrusion tools.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

M2 HIGH SPEED STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤248 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

M2 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | |||||||

| C | Si | Mn | Cr | Mo | V | W | ||

| ASTM | M2 | 0.78~0.88 | 0.20~0.45 | 0.15~0.40 | 3.75~4.50 | 4.50~5.50 | 1.75~2.20 | 5.50~6.75 |

| DIN/W-Nr. | S6-5-2/1.3343 | 0.86~0.94 | ≤0.45 | ≤0.40 | 3.80~4.50 | 4.70~5.20 | 1.70~2.00 | 6.00~6.70 |

| JIS | SKH51 | 0.80~0.90 | ≤0.40 | ≤0.40 | 3.80~4.50 | 4.50~0.50 | 1.60~2.20 | 5.50~6.70 |

| GB | W6Mo5Cr4V2 | 0.80~0.90 | 0.20~0.40 | 0.15~0.40 | 3.80~4.40 | 4.50~5.50 | 1.75~2.20 | 5.50~6.75 |

APPLICATION

M2 high speed steel is often used in cold forging dies, precision stamping dies, powder pressing dies, shear dies, plastic dies with glass fibers, etc. Die suitable for bearing vibration and impact load: deep drawing die, punching die. Metal cutting blades, cold heading and extrusion tools, etc.

M2 STEEL CHARACTERISTICS

M2 steel is a molybdenum based high-speed steel with low carbide heterogeneity and high toughness. Its main advantage lies in its good hardness and wear resistance, so it is often used to manufacture cutting tools for difficult to cut materials. Meanwhile, due to its high tendency towards carbides, the requirements for heat treatment protection are relatively strict. In addition, M2 steel is also suitable for tools that can withstand vibration and impact loads, such as deep drawing molds, punching molds, etc. However, it should be noted that this material is prone to overheating, so temperature should be strictly controlled during the quenching and heating process. In practical applications, such as metal cutting saw blades, cold heading and extrusion tools, the figure of M2 steel can be seen.

The main component of M2 steel is high-speed steel, which contains 0.8% molybdenum. This special alloy composition gives M2 steel excellent hardness and wear resistance. During high-speed cutting, M2 steel can maintain high hardness and red hardness, effectively improving cutting efficiency and extending tool life. In addition, M2 steel also has good resistance to thermal softening, enabling it to maintain good cutting performance in high-temperature environments.

Another notable feature of M2 steel is its low unevenness of carbides. Carbide is an important structure in high-speed steel, which directly affects the properties of high-speed steel. The non-uniformity of carbides can lead to uneven hardness and toughness of high-speed steel, thereby affecting the service life and cutting effect of cutting tools. M2 steel effectively reduces the non-uniformity of carbides by optimizing alloy composition and production process, thereby improving the performance of high-speed steel.

M2 steel also has high toughness. Toughness refers to the ability of a material to resist fracture under external forces. During the cutting process, the tool will be subjected to significant impact and vibration forces. If the material's toughness is insufficient, it is easy to cause the tool to fracture. M2 steel improves its toughness by adding an appropriate amount of elements such as tungsten and vanadium, enabling it to maintain stable performance under high impact and vibration forces.

M2 steel has a wide range of applications in practical applications. Firstly, due to its good hardness and wear resistance, M2 steel is widely used in the manufacturing of cutting tools for difficult to cut materials. For example, in the metal processing industry, M2 steel can be used to manufacture cutting tools such as drills, milling cutters, turning tools, etc; In the wood processing industry, M2 steel can be used to manufacture cutting tools such as saw blades and planers. These tools can maintain high hardness and wear resistance during the cutting process, thereby improving cutting efficiency and extending tool life.

Secondly, due to its good thermal softening resistance, M2 steel can be used to manufacture cutting tools that withstand high temperature environments. For example, in the steel smelting industry, M2 steel can be used to manufacture cutting tools in the furnace; In the aerospace industry, M2 steel can be used for cutting tools for manufacturing engine parts. These tools can still maintain good cutting performance in high-temperature environments, thus meeting the needs of special industries.

Finally, due to its high toughness, M2 steel can be used to manufacture tools that withstand vibration and impact loads. For example, in the automotive manufacturing industry, M2 steel can be used to manufacture deep drawing molds, punching molds, etc; In the construction industry, M2 steel can be used to manufacture steel bar shearing machines, steel plate shearing machines, etc. These tools can maintain stable performance during the process of withstanding vibration and impact loads, thus ensuring the smooth progress of production.