- Home

- >

- Products

- >

- S136 / S136H

- >

S136 / S136H

S136 steel is a high-end mirror mold steel with excellent corrosion resistance and polishing performance, with a hardness of 50-54HRC. S136 steel is particularly suitable for precision optical molds and corrosive plastic molding.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

S136 TOOL STEEL

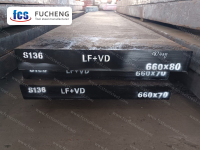

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤225 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

S136 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | |||||||

| C | Si | Mn | Cr | |||||

| ASSAB | S136 | 0.26~0.42 | 0.30 | ≤1.00 | 13.0 | |||

| ASTM | 420SS | 0.30~0.40 | ≤1.00 | 0.15~0.40 | 12.0~14.0 | |||

| DIN/W-Nr. | X42Cr13/1.2083 | 0.38~0.45 | ≤1.00 | ≤0.40 | 12.5~13.5 | |||

| JIS | SUS420J2 | 0.26~0.40 | ≤1.00 | ≤0.40 | 12.0~14.0 | |||

APPLICATION

S136 steel is mainly used to manufacture corrosion-resistant molds with high precision and high surface requirements, especially suitable for injection molding of corrosive plastics such as PVC and acetate. S136 steel can maintain the smoothness of the mold cavity for a long time without additional rust prevention treatment in humid environments.

The polishing performance of S136 steel mirror makes it the preferred material for high-end molds such as optical lenses, medical devices, and transparent plastic products. At the same time, molds with high wear resistance requirements such as electronic components and disposable tableware also widely use S136 steel. The purity improved by the electroslag remelting process can also meet the working requirements of thermosetting plastic molding and precision extrusion molds.

S136 STEEL CHARACTERISTICS

S136 steel is a chromium nickel molybdenum vanadium alloy steel known for its excellent corrosion resistance, wear resistance, and high hardness. After long-term use, the surface of the mold cavity of this steel can still maintain its original smooth state, so the maintenance cost is lower. In addition, it also has excellent production characteristics. For service life requirements that require long-term work or the number of parts reaching over 1 million, a more suitable method of use is to undergo quenching and low-temperature tempering treatment.

S136 mold steel can be used in a quenched and tempered state with a hardness of 48-54HRC for high-quality cutting and processing. These characteristics make S136 mold steel widely used in the field of mold manufacturing, especially when operating or storing in humid environments, without requiring special protection. Overall, S136 steel has been widely recognized and applied in the mold manufacturing industry due to its excellent corrosion resistance, wear resistance, high hardness, and cutting and processing properties.

S136 steel has excellent corrosion resistance. It contains elements such as chromium, nickel, molybdenum, and vanadium, which can form a dense oxide film, effectively preventing steel from coming into contact with the external environment, thereby reducing the possibility of corrosion. This makes S136 steel particularly suitable for manufacturing molds that require working in humid environments, such as food molds, cosmetics molds, etc.

S136 steel has good wear resistance. During use, S136 steel can resist wear and damage, maintaining stability in its shape and size. This makes S136 steel particularly suitable for manufacturing molds that need to withstand significant wear, such as cold drawing molds, cold heading molds, etc.

S136 steel has high hardness. When used in a quenched and tempered state with a hardness of 48-54HRC, S136 steel can maintain high strength and hardness, and is less prone to deformation and damage. This makes S136 steel particularly suitable for manufacturing molds that need to withstand significant impact forces, such as stamping molds, extrusion molds, etc.

S136 steel also has good cutting and processing properties. During the machining process, S136 steel can be easily cut, ground, and drilled, resulting in high machining efficiency. This makes S136 steel particularly suitable for manufacturing molds that require high-precision processing, such as electronic molds, optical molds, etc.

S136 steel also has good polishing performance. During the polishing process, S136 steel can easily remove surface oxide scale and impurities, achieving a smooth surface quality. This makes S136 steel particularly suitable for manufacturing molds that require high smoothness, such as plastic molds, optical molds, etc.