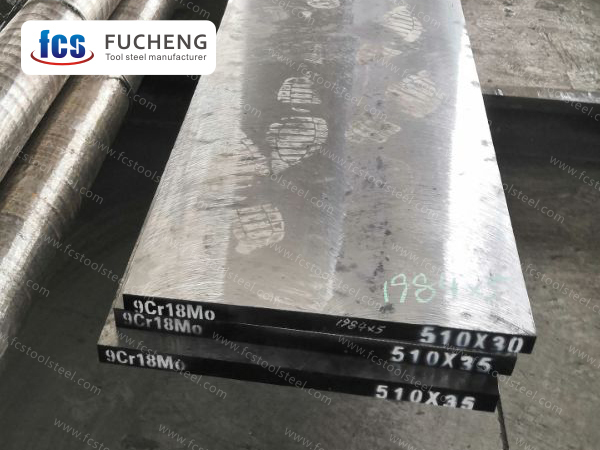

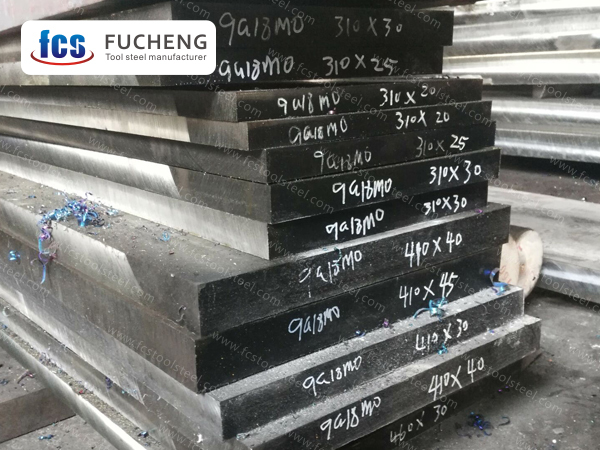

9Cr18Mo Plastic Mould Steel

9Cr18Mo steel is suitable for bearing, turbine blade, nozzle, valve, plate ruler, cutter and scissors with good corrosion resistance.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

9Cr18Mo TOOL STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

9Cr18Mo STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | |||||

| C | Si | Mn | Cr | Mo | ||

| GB | 9Cr18Mo | 0.95~1.10 | ≤0.80 | ≤0.80 | 16.00~18.00 | 0.40~0.70 |

| ASTM | 440C | 0.95~1.20 | ≤1.00 | ≤1.00 | 16.00~18.00 | ≤0.75 |

APPLICATION

9Cr18Mo steel is suitable for bearing, turbine blade, nozzle, valve, plate ruler, cutter and scissors with good corrosion resistance.

9Cr18Mo Steel Characteristics

9Cr18Mo steel is a high carbon chromium martensitic stainless bearing steel that has high hardness and wear resistance after quenching, and high dimensional stability at high and low temperatures. In addition, 9Cr18Mo stainless steel also has good processing and heat treatment properties, and its hardness and toughness can be adjusted through quenching and tempering treatment methods.

In terms of physical properties, the density of 9Cr18Mo stainless steel is 7.70g/cm ³, The coefficient of thermal expansion is 10.0 × 10 ^ -6/℃, thermal conductivity of 24.2W/(m · K), specific heat capacity of 0.50J/(g · ℃), and linear expansion coefficient of 15.0 × 10 ^ -6/℃.

The presence of molybdenum increases the passivation effect of stainless steel, resulting in higher hardness and tempering stability of 9Cr18Mo stainless steel after quenching. Therefore, 9Cr18Mo not only has excellent strength and corrosion resistance, but also can be used under high temperature and high load conditions, demonstrating good heat resistance and wear resistance. These characteristics make it widely used in the manufacturing of automotive engine parts, aerospace equipment, and other fields.