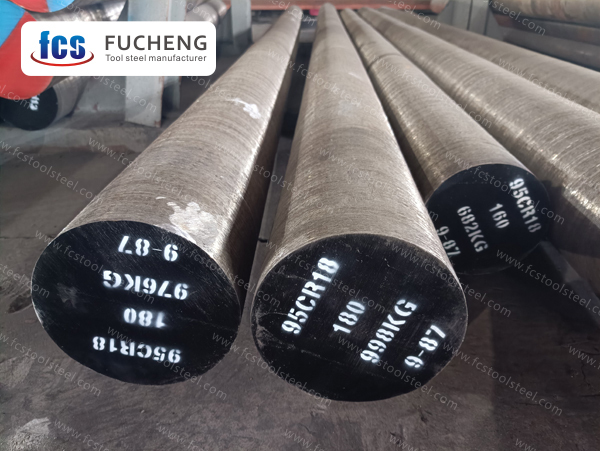

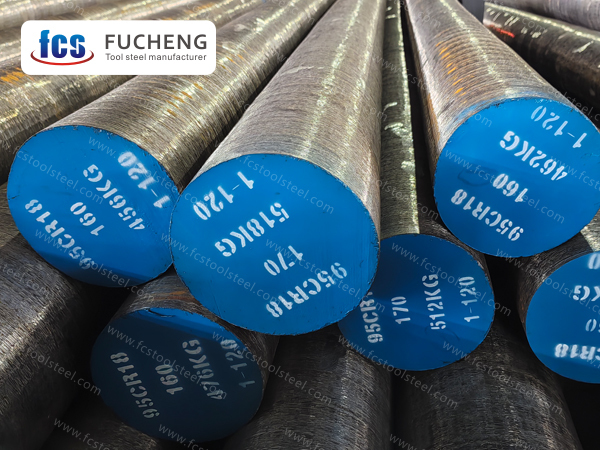

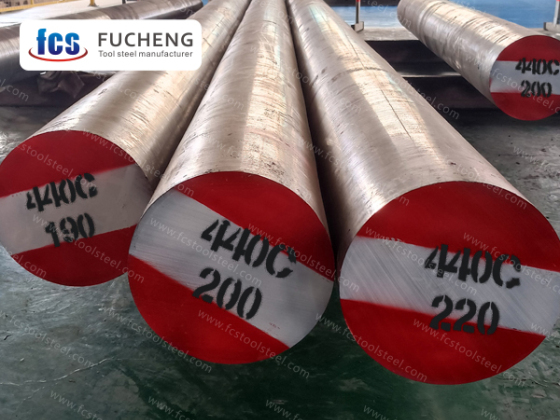

95Cr18 Stainless Steel

95Cr18 Stainless steel is used as a cutting tool for stainless steel slicing machinery, as well as cutting tools, surgical blades, and high wear resistant equipment parts.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

95Cr18 STAINLESS STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

95Cr18 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||||||

| C | Si | Mn | P | S | Cr | Mo | V | Cu | Ni | ||

| ASTM | 440C | 0.95~1.20 | ≤1.00 | ≤1.00 | 16.00~18.00 | ≤0.75 | |||||

| GB | 95Cr18 | 0.90~1.00 | ≤0.80 | ≤0.80 | ≤0.025 | ≤0.020 | 17.00~19.00 | ≤0.20 | ≤0.10 | ≤0.30 | ≤0.30 |

APPLICATION

95cr18 stainless steel belongs to high carbon and high chromium martensitic stainless steel, which has high hardness, high wear resistance, and corrosion resistance after quenching. It is commonly used for slicing machinery, cutting tools, surgical blades, and high wear resistant equipment parts.

95cr18 Stainless Steel Characteristics

95Cr18 steel is a martensitic stainless steel. This type of stainless steel belongs to high carbon and high chromium martensitic stainless steel, which is one of the stainless steel varieties with the highest carbon content and belongs to high alloy special steel. Therefore, it has excellent wear resistance and corrosion resistance.

In terms of specific performance, 95Cr18 steel exhibits extremely high corrosion resistance and can maintain good stability in various corrosive media. It has excellent corrosion resistance for corrosive media such as strong acids, alkalis, and salt solutions. In addition, it also has good mechanical properties and is widely used in the manufacturing of high-end corrosion-resistant bearings, cutting tools, automotive engines, and key components for household appliances.

Although 95Cr18 steel has poor corrosion resistance compared to low-carbon stainless steel, it still exhibits excellent rust resistance and corrosion resistance in atmospheric, water, and certain acid and salt aqueous solutions. In practical applications, 95Cr18 steel is often used to make stainless slicing machinery cutting tools, cutting tools, surgical blades, and high wear resistant equipment parts.

Firstly, the corrosion resistance of 95Cr18 steel is excellent. Due to its content of up to 18% chromium, it can form a dense chromium oxide protective film when encountering oxidizing substances. This protective film can effectively prevent further oxidation reactions, thereby greatly improving the corrosion resistance of the steel. In addition, 95Cr18 steel also contains a certain amount of nickel element. The addition of nickel element can improve the oxidation resistance of the steel and further improve its corrosion resistance.

Secondly, 95Cr18 steel has good hardness and strength. Due to its high carbon content, steel has a higher hardness and strength. This gives 95Cr18 steel great advantages when making cutting tools, stamping molds, and other tools that require high strength and hardness. Meanwhile, due to its high hardness, it has a longer service life when making cutting tools.

Once again, 95Cr18 steel has good heat resistance. Due to its high chromium content, steel can still maintain good stability in high-temperature environments. This gives 95Cr18 steel great advantages in making equipment and tools for use in high-temperature environments. For example, it can be used to make high-temperature furnaces, heat treatment equipment, etc.

However, although 95Cr18 steel has many advantages, it also has some limitations. Firstly, due to its high carbon content, the toughness of steel is poor. This makes it possible to choose other types of steel when making tools that require high toughness. Secondly, due to its high chromium content, the cost of steel is higher. This makes it possible to choose other types of steel in some cost sensitive applications. Finally, due to its high content of carbon and chromium elements, steel needs to be particularly careful during heat treatment to prevent cracks and other heat treatment defects.