- Home

- >

- Products

- >

- 38CrMoV5-3 Steel

- >

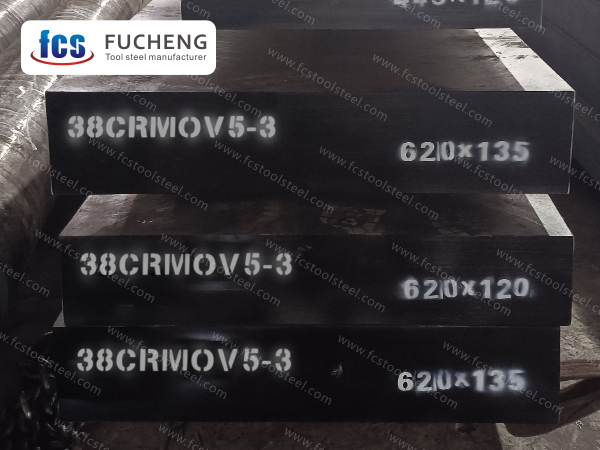

38CrMoV5-3 Steel

38CrMoV5-3 steel has high high temperature strength, high temperature wear resistance and crack propagation resistance.

38CrMoV5-3 steel is usually used for hot forging dies with high service life requirements, aluminum and zinc die casting dies. Aluminum alloy, copper alloy extrusion die, complex extrusion die.

- Fucheng

- China

- 1 Month

- 2000 Tons/Month

- Information

38CrMoV5-3 STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤235 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

38CrMoV5-3 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| DIN/W-Nr. | 38CrMoV5-3/1.2367 | 0.35~0.40 | 0.30~0.50 | 0.30~0.50 | 4.80~5.20 | 2.70~3.20 | 0.40~0.60 |

APPLICATION

38CrMoV5-3 steel is usually used for hot forging dies with high service life requirements, aluminum and zinc die casting dies. Aluminum alloy, copper alloy extrusion die, complex extrusion die.

38CrMoV5-3 Steel Properties

38CrMoV5-3 mold steel is a high-quality hot work mold steel, which mainly includes high toughness, excellent high-temperature resistance, and excellent heat fatigue and wear resistance at high temperatures. This material is very suitable for manufacturing products with high quality requirements. Compared with traditional smelting steel, its isotropy is better, which means it has excellent toughness and plasticity in all directions. In addition, 38CrMoV5-3 mold steel also has good processability and heat treatment performance.

38CrMoV5-3 has high strength and wear resistance, making it an ideal mold steel material. However, attention should be paid to factors such as temperature, coolant, and surface quality during use, as these factors may affect the performance and service life of mold steel.

It is also worth mentioning that 38CrMoV5-3 is an electroslag remelting hot working steel, which makes its structure more uniform, material more purified, and has high isotropy, thereby possessing excellent high-temperature strength, high-temperature wear resistance, and crack propagation resistance. Therefore, in high demand application scenarios, such as those requiring heat resistance, high-temperature toughness, heat fatigue resistance, and wear resistance, 38CrMoV5-3 is an excellent choice.

Due to its superior mechanical properties and good heat treatment performance, 38CrMoV5-3 mold steel is widely used in the manufacturing of various mold products such as plastic molds and die-casting molds.