- Home

- >

- Products

- >

- 1.2746 Tool Steel

- >

1.2746 Tool Steel

1.2746 mold steel is a high-performance tool steel with good wear resistance, toughness, and thermal fatigue resistance.

- Fucheng Steel

- China

- 1 Month

- 2000 Tons/Month

- Information

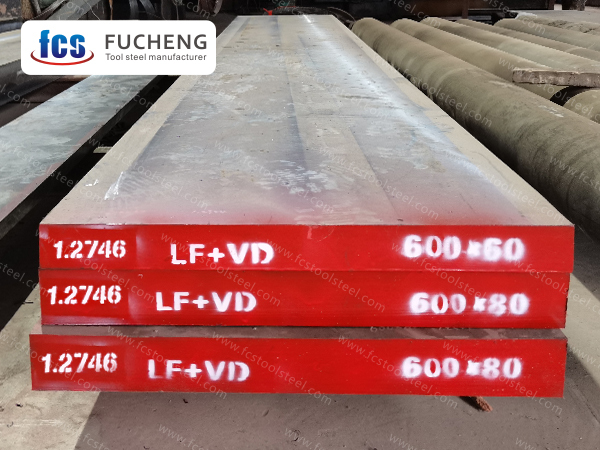

1.2746 TOOL STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤295 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

1.2746 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | |||||||

| C | Si | Mn | Cr | Mo | V | Ni | ||

| DIN/W-Nr. | 1.2746 | 0.41~0.49 | 0.15~0.35 | 0.60~0.80 | 1.40~1.60 | 0.73~0.85 | 0.45~0.55 | 3.80~4.20 |

APPLICATION

1.2746 steel is commonly used in the manufacture of die-casting molds, plastic molds, etc. The chemical composition of the steel is carefully blended to achieve high hardness and strength after appropriate heat treatment, while maintaining a certain degree of toughness to cope with complex working environments and stress conditions.

1.2746 Steel Characteristics

1.2746 mold steel has good hardenability and can achieve uniform hardness distribution even in larger sections. 1.2746 steel has high toughness and can effectively resist impact and fatigue loads, reducing the probability of cracking during mold use. 1.2746 steel has excellent wear resistance and can significantly extend the service life of molds, reducing size changes and surface quality degradation caused by wear. 1.2746 steel has excellent thermal stability and can maintain good mechanical properties and dimensional stability even in high temperature environments.

Moreover, the processing performance of 1.2746 mold steel is good, and mechanical processing operations such as cutting and grinding are relatively easy, providing convenience for the manufacturing and repair of molds.