- Home

- >

- Products

- >

- X210Cr12 Steel

- >

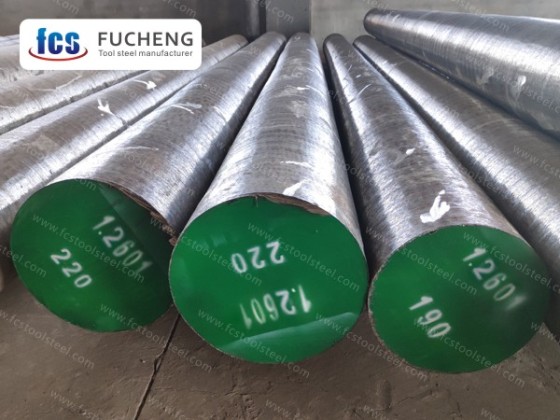

X210Cr12 Steel

X210Cr12 steel has high wear resistance and long service life, and is suitable for various cold stamping dies, cold shear blades, thread take-up plates and other complex and possibly deformed tool dies.

- Fucheng Steel

- China

- 1 Month

- 2000 Tons/Month

- Information

X210Cr12 TOOL STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

X210Cr12 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||

| C | Si | Mn | Cr | ||

| GB | Cr12 | 2.00~2.30 | ≤0.40 | ≤0.40 | 11.5~13.0 |

| ASTM | D3 | 2.00~2.35 | 0.10~0.60 | 0.20~0.60 | 11.0~13.5 |

| DIN/W-Nr. | X210Cr12/1.2080 | 1.9~2.20 | 0.10~0.40 | 0.15~0.45 | 11.0~12.0 |

| JIS | SKD1 | 1.9~2.20 | 0.10~0.60 | 0.20~0.60 | 11.0~13.0 |

APPLICATION

X210Cr12 Steel is suitable for the manufacture of cold working dies with complex shape and requiring wear resistance, small deformation and stress, such as silicon steel sheet punching die, thread rolling die and drawing die.

X210Cr12 STEEL CHARACTERISTICS

X210Cr12 steel is an alloy tool steel mainly composed of high carbon and high chromium. During the heat treatment process, X210Cr12 steel first needs to undergo spheroidizing annealing treatment to eliminate forging stress and improve its cutting performance. Then quenching and tempering are carried out to obtain the required hardness and toughness. The quenching temperature is usually selected between 860 ℃ and 900 ℃, which can ensure the obtaining of a mixed structure of martensite and residual austenite. The tempering temperature is selected between 450 ℃ and 650 ℃ as needed to achieve the required strength and toughness.

Due to its high content of carbon (mass fraction 2.00%~2.30%) and chromium (mass fraction 11.00%~13.00%), X210Cr12 steel belongs to the type of ledeburite steel, which endows it with excellent hardenability, hardenability, and wear resistance. Small quenching deformation is another characteristic, but it should be noted that if the distribution of carbides is uneven, it may lead to multi-directional and irregular deformation. Therefore, although X210Cr12 steel has excellent performance, the quality of its microstructure is a key factor determining its final performance.

The main elements of X210Cr12 steel are carbon and chromium, with carbon content ranging from 2.00% to 2.30% and chromium content ranging from 11.00% to 13.00%. The ratio of these two elements is very important because they determine the hardness and wear resistance of steel. Carbon is a strong hardening element that can improve the hardness and strength of steel, but also increase its brittleness. Chromium is a strengthening element that can improve the hardness and wear resistance of steel, as well as increase its oxidation resistance.

Secondly, the heat treatment process of X210Cr12 steel also has an important impact on its properties. Generally speaking, X210Cr12 steel requires quenching and tempering treatment. Quenching is the process of heating steel above a critical temperature and then rapidly cooling it to form a martensitic structure with carbon and chromium in the steel. Tempering is the process of reheating the quenched steel to a certain temperature and then slowly cooling it to transform the martensitic structure into a tempered sorbite structure. This process can eliminate the stress generated during the quenching process, improve the toughness and stability of the steel.

Finally, the microstructure of X210Cr12 steel is also an important factor affecting its properties. Due to the high content of carbon and chromium in X210Cr12 steel, its structure is mainly composed of martensite and carbides. Martensite is a hard and brittle structure that can improve the hardness and strength of steel, but also increase its brittleness. Carbide is a hard and wear-resistant structure that can improve the wear resistance of steel, but also increase its brittleness. Therefore, how to control the distribution and size of carbides is the key to improving the properties of X210Cr12 steel.